- Machine-tools

- Machining Center

- 3-axis machining center

- FFG Europe & Americas

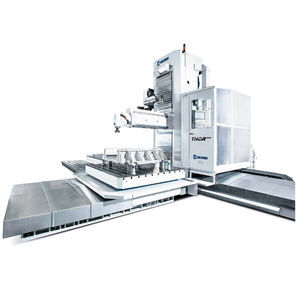

3-axis CNC milling center JOBS GRAND SPEEDERverticalgantrydouble-column

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- gantry, double-column

- Machined material

- for composites

- Applications

- for the automobile industry, for the aerospace industry

- Other characteristics

- high-precision, high-speed

- Y travel

5,000 mm

(196.85 in)- Z travel

2,500 mm

(98.43 in)

Description

Vertical Jobs Grand Speeder high-speed milling centers with an electro-welded structure have a traveling crossbeam that moves on two columns. The special machine architecture enables high positioning and configuration flexibility and ensures maximum operator safety as well as optimal monitoring of production processes.

ADVANTAGES

HOW TO BENEFIT FROM JOBS GRAND SPEEDER MILLING CENTERS

HIGH MACHINING CAPACITIES

Travels on vertical Jobs Grand Speeder gantry milling centers – up to 5,000 mm on the Y-axis and up to 2,500 mm on the Z-axis – enables high machining capacities. The overhead gantry structure with multi-drive on all axes ensures a high dynamic up to 60 m/min and an acceleration up to 5 m/s.

TOP EFFICIENCY

Jobs Grand Speeder high-speed milling centers are characterized by low hourly and operating costs. Maintenance costs are also significantly reduced.

FLEXIBLE USE

Jobs Grand Speeder high-speed milling centers can be used both for wet machining with cooling lubricant and chip management as well as for dry machining using the efficient Jobs extraction system.

PERFECT FOR COMPOSITES

Vertical Jobs Grand Speeder milling centers can be equipped with Compoflex, the versatile Jobs device for clamping parts made of composites.

Jobs Grand Speeder high-speed milling centers with a movable crossbeam are used in applications such as mold, model and prototype construction for the aerospace industry as well as for sports cars and boats. Benefit from top precision and surface quality at maximum machining speed.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- High-productivity CNC machining center

- Column type CNC machining center

- Aluminum CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.