- Machine-tools

- Machining Center

- CNC drilling and milling machine

- FFG Europe & Americas

CNC drilling and milling machine JOBS ROBODRIMcolumn type6-axis

Add to favorites

Compare this product

Characteristics

- Type

- CNC

- Structure

- column type

- Number of axes

- 6-axis

Description

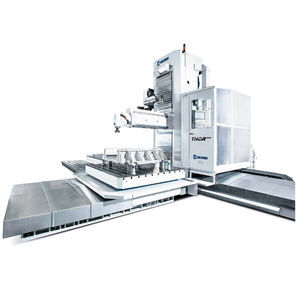

The Jobs Robodrim is a drilling and milling robot that uses Cartesian coordinates. It has moving columns on which a 2- or 3-polar axis machining and/or handling robot can be deployed. As a highly productive milling machine, the Jobs Robodrim was specifically designed for machining large aircraft parts. The Robodrim can also be equipped with a series of sensor systems, e.g. for automatic detection of workpiece geometry, management of material batch processing, process control or maintenance management.

ADVANTAGES

HOW TO BENEFIT FROM JOBS ROBODRIM MILLING CENTERS

TOP EFFICIENCY

Jobs Robodrim high-speed milling centers are characterized by low hourly and operating costs. Maintenance costs are also significantly reduced.

FLEXIBLE USE

Different travels and outputs on Jobs Robodrim high-speed milling centers cater for a wide range of applications.

READY FOR INDUSTRY 4.0

Jobs Robodrim high-speed milling centers can be equipped with the latest sensor technology – from systems for automatically detecting workpiece geometry, detection systems for shape variables (image processing/ analysis), management systems for material batch processing, process control systems to data acquisition systems for traceability or systems for efficient maintenance management via remote monitoring.

Jobs Robodrim high-speed milling centers with moving columns were specifically developed for machining large aircraft parts and here their performance, efficiency and flexibility advantages are perfectly demonstrated. Benefit from top precision and surface quality at maximum machining speed.

Catalogs

No catalogs are available for this product.

See all of FFG Europe & Americas‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.