- Machine-tools

- Machining Center

- 3-axis machining center

- FFG Europe & Americas

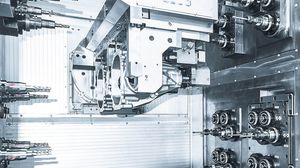

3-axis CNC machining center MAG SPECHT DUOvertical2-spindleHSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Number of spindles

- 2-spindle

- Spindle mount

- HSK A-63, HSK-63, HSK-100, HSK-A 100

- Number of tool stations

- 60 tools

- Applications

- for the automobile industry

- Other characteristics

- high-performance, high-productivity, compact, high-precision, modular

- X travel

510 mm, 630 mm, 800 mm

(20.08 in, 24.8 in, 31.5 in)- Y travel

600 mm, 630 mm, 730 mm

(23.62 in, 24.8 in, 28.74 in)- Z travel

660 mm, 700 mm, 860 mm, 900 mm

(25.98 in, 27.56 in, 33.86 in, 35.43 in)- Rotational speed

8,000 rpm, 10,000 rpm, 16,000 rpm, 18,000 rpm

(50,265 rad.min-1, 62,832 rad.min-1, 100,531 rad.min-1, 113,097 rad.min-1)- Power

39 kW, 42 kW, 52 kW

(53.03 hp, 57.1 hp, 70.7 hp)- Tool weight (max)

12 kg, 18 kg

(26.5 lb, 39.7 lb)- Tool-changing time

3 s, 3.5 s

- Weight

Max.: 24,000 kg

(52,910.94 lb)Min.: 16,000 kg

(35,273.96 lb)- Overall length

Max.: 4,950 mm

(194.9 in)Min.: 4,150 mm

(163.4 in)- Overall width

Max.: 3,750 mm

(147.6 in)Min.: 3,100 mm

(122 in)- Overall height

3,470 mm, 3,650 mm, 3,700 mm, 3,800 mm

(136.6 in, 143.7 in, 145.7 in, 149.6 in)

Description

MAG SPECHT DUO CNC machining centers are ideal as interlinked multi-machine systems. They can also be used as a stand-alone machine and in manufacturing cells. The convincing feature of these double-spindle CNC systems is their modular structure, which provides maximum flexibility and makes them individually configurable. This makes it possible to use ball screw or linear motors for axis drive. Unique axis compensation achieves the same precision as that of single-spindle CNC machines.

INDUSTRIES

Equal to any challenge – not only in these industries

Foundries

System solutions for powertrain and structural parts

System partner for the efficient production of cubic engine and transmission parts

E-Mobility

Exact precision manufacturing of engine and structural parts

ADVANTAGES

HOW TO BENEFFIT FROM MAG SPECHT DUO CNC MACHINING CENTERS

Maximum flexibility

A wide range of standardized parts enable single- or double-spindle MAG SPECHT CNC machines to be configured for specific customer requirements. Double-spindle CNC systems are available for spindle spacing from 540 to 810 mm.

Maximum yield rates

MAG SPECHT DUO CNC systems offer the highest yield rates with minimum footprint thanks to their compact design. The MAG SPECHT 450 DUO only requires 11.2 m², for example.

MAG SPECHT CNC machining centers enable the shortest chip-to-chip times to under 2.5 seconds due to highly dynamic pick-up discs with top tool capacity. Rapid traverse permits up to 120 m/min and acceleration up to 1.5 m/s.

VIDEO

Catalogs

SPECHT® 500 DUO

8 Pages

Other FFG Europe & Americas products

MACHINING CENTERS AND CNC SYSTEMS

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Bridge CNC milling machine

- Precision CNC milling machine

- Horizontal CNC machining center

- CNC machining center with pallet changer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.