- Products

- Catalogs

- News & Trends

- Exhibitions

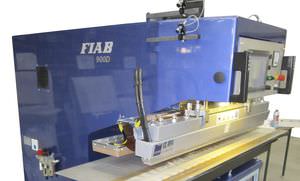

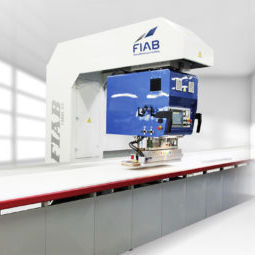

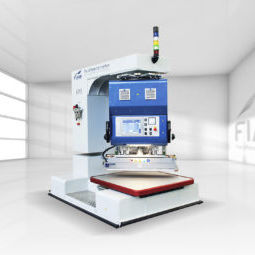

Laser welding machine SHUTTLEautomaticdouble-sided

Add to favorites

Compare this product

Characteristics

- Technique

- laser

- Operational mode

- automatic

- Other characteristics

- double-sided

Description

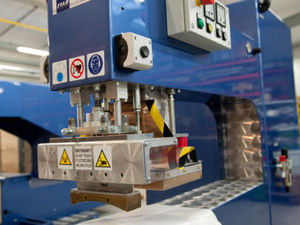

FIAB SHUTTLE TABLE is a machine equipped with single or double-sided shuttle table. Possibility of applying of cutting - and - welding tools in various shapes. This highly customized machine is dedicated especially to automotive and medical industry. The welding is designed as a two – stage process. Table sections are managed independently.

The operator prepares the product on the table and places the tools on top of it (the tool can be also fixed with the press). Then he presses the start button and the machine starts welding the product in two steps automatically according to the pre-set recipe. The recipe can be stored on the computer, on a flash card or USB memory stick. You can save unlimited number of recipes.

Standard design:

- round return from four sides is for safety and functional production,

- four pillar press with cylinders for exact and equal press pressure over all area,

- self-centering system with locking screws.

If you are going to produce cleats for conveyor belts – we can offer you a special model FIAB FT, which has a similar construction to FIAB Shuttle Table regarding the press, but it’s not equipped with sliding table.

VIDEO

Related Searches

- Welding system

- Automatic welding system

- Laser welding system

- Arc welding system

- Precision welding system

- Compact welding system

- CNC welding system

- Fiber laser welding system

- Ultrasonic welding system

- Integrated welding system

- High-frequency welding system

- Rotary welding system

- Wedge welding machine

- Pulse welding machine

- Textile welding system

- Hot plate welding machine

- Servo-driven welding system

- Vacuum welding machine

- Gantry welding system

- Double-sided welding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.