Robotic palletizer and depalletizer cheesefor cardboard boxescase

Add to favorites

Compare this product

Characteristics

- Type

- robotic

- Product applications

- cheese, for cardboard boxes, case

- Other characteristics

- automatic, for the food industry

Description

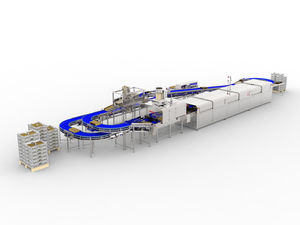

FIBOSA use the latest technologies to palletising and de-palletising process using robots as an automatic system for filling and emptying plastic boxes. This provides a lot of advantages such as elimination of manual labour, better preservation boxes and pallets, high hygiene level and flexibility which allows to work with a different kind of cheese formats and production capacity. The palletizing process starts at the end of the cheese conditioning phase. Robot №1 establish clean plastic box where the cheese will be placed in. After filling robot lifts, places and stacks the box on previously installed pallet placed in the loading area. This cycle repeats until the pallet fills up with boxes and it will be removed to unloading area where forklift will transport it to the maturing room. When the maturation phase is complete the pallets are moved to de-palletisation and washing area and then they moves to packaging station. Robot №2 unload the boxes from the pallet and place them at the entrance of cantilever full of boxes for automatic rotation. Then robotic section removes the empty box and places it to the entrance of washing tunnel, meanwhile cheese is placed on the conveyor belt which moved it to packaging station. This process continues consistently until the pallet is completely emptied. If it’s necessary it can be located at the entrance of the same washing tunnel. Finally Robot №3 installs the pallets and removes clean boxes, leaving them ready to be moved with forklift to the pallet loading area, where this cycle will restart.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FIBOSA‘s catalogsRelated Searches

- Packing machine

- Automatic packing machine

- Packing machine for the food industry

- Vacuum packing machine

- Packaging machine for the food industry

- Packing machine with sealing

- Packing machine with conveyor

- Flowpack packing machine

- Cheese packing machine

- Palletizer and depalletizer

- Automatic palletizer and depalletizer

- Robotic palletizer and depalletizer

- Palletizer and depalletizer for the food industry

- Cardboard box palletizer and depalletizer

- Cheese palletizer and depalletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.