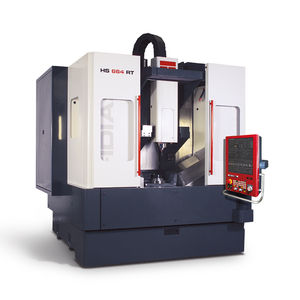

3-axis CNC machining center FMS series5-axisverticalHSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis, 5-axis

- Spindle orientation

- vertical

- Spindle mount

- HSK A-63, HSK-100-A

- Other characteristics

- with integrated pallet changer, automated loading/unloading

- X travel

850 mm, 2,000 mm, 4,000 mm

(33.46 in, 78.74 in, 157.48 in)- Y travel

950 mm, 1,000 mm, 2,000 mm, 2,500 mm

(37.4 in, 39.37 in, 78.74 in, 98.43 in)- Z travel

600 mm, 1,000 mm

(23.62 in, 39.37 in)- Rotational speed

6,000 rpm, 24,000 rpm

(37,699 rad.min-1, 150,796 rad.min-1)- Power

30 kW, 55 kW

(40.79 hp, 74.78 hp)- Work feed X-axis

24,000 mm/min, 25,000 mm/min, 45,000 mm/min

(16 in/s, 16 in/s, 30 in/s)- Work feed Y-axis

24,000 mm/min, 25,000 mm/min, 45,000 mm/min

(16 in/s, 16 in/s, 30 in/s)- Table load capacity

2,000 kg, 3,000 kg, 15,000 kg

(4,409 lb, 6,614 lb, 33,069 lb)

Description

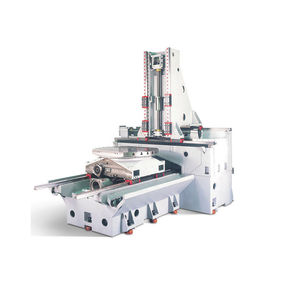

The new FMS system designed by Fidia is equipped with a sophisticated software that optimizes and exalts its operative characteristics. This system is the Fidia answer to the more and more pressing request of increasing the workshop automation level, and integrates a powerful and versatile pallet system.

The FMS platform serves independent working islands of minimum 2 machines each, and allows for the complete machining of complex components in 3 or 5 axes, starting from the rough part.

This system is the ideal solution for a highly developed workshop environment, requiring the best standards of automation levels.

The powerful dedicated software automatically manages and optimizes the production flow without intervention of the machine operator. Such a way of functioning pursues the following goals:

reduction of waiting times;

simplification of programming;

optimization of tool wear-out;

full monitoring of production flow;

reduction of human error risks;

never-ending 7/7 & 24/24 production.

Each machine can be also used in a standalone way, nonetheless granting the normal functioning of the FMS system with the other machines.

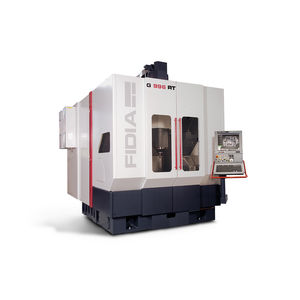

Island configuration

No. 1 G996 machine for roughing out;

No. 2 G996 machines for finishing;

No. 1 automatic pallet change system;

No. 1 manual loading/unloading station;

No. 4 stacking stations;

No. 6 pallets;

Pallet capacity 2000 kg (4409 lbs);

Total length of installed system 17 m (670“).

The system can also work in unmanned machining mode.

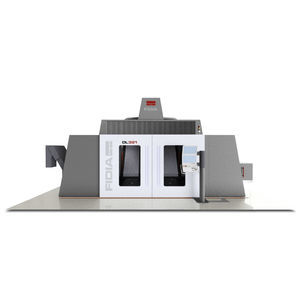

Island configuration

No. 4 D321/M machines;

No. 1 automatic pallet change system;

No. 5 stacking stations;

No. 8 pallets;

Pallet capacity 15000 kg (33069 lbs);

Total length of installed system 32 m (1260“).

Catalogs

No catalogs are available for this product.

See all of FIDIA‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Aluminum CNC machining center

- Milling machine

- CNC machining center with pallet changer

- Compact CNC machining center

- 3-axis milling machine

- Machining center for the automobile industry

- CNC machining center with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.