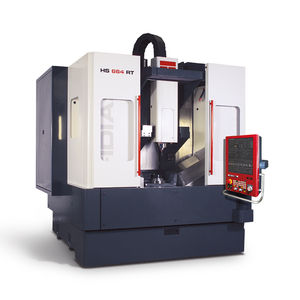

5-axis CNC machining center BSE seriesverticalbridgemilling

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- bridge

- Associated functions

- milling

- Other characteristics

- high-speed, high-performance, high-precision, high-rigidity

- X travel

1,100 mm, 1,750 mm, 2,200 mm

(43.31 in, 68.9 in, 86.61 in)- Y travel

600 mm, 1,000 mm, 1,750 mm

(23.62 in, 39.37 in, 68.9 in)- Z travel

500 mm, 750 mm

(19.69 in, 29.53 in)

Description

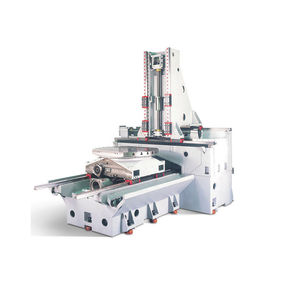

This line of machining centers is characterized by the moving table and fixed bridge type structure. High dynamics and machine accelerations, in addition to the use of electrospindles with high rates of rotations, makes this machine ideal whenever the high speed milling technology is required.

With High Rigidity, High precision and High Speed, the Fidia BSE represents the evolution in Mold&Die machining .

Spindle

BSE 1000 milling centres can be equipped with different spindles designed to satisfy the most advanced market requirements:

The 18.000 Rpm grease lubricated electrospindle allows high speed finishing and High Speed roughing when the 27 Kw/64.5 Nm is delivered.

Optionally, 24.000 Rpm is also available for the high quality finishing milling. Spindle is water cooled to control thermal effects.

Large Workpiece load & Traverse capacity:

• - 1.100 x 600 x 500 mm travels on X/Y/Z

• - 700 mm Distance betwwen Columns

• - 1.220 x 600 mm Table size with 1.500 kg. work piece load.

• - The wide distance 700mm between twin column, allows the most convenience mounting of medium workpiece, Þxture or rotary table etc.

Catalogs

No catalogs are available for this product.

See all of FIDIA‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Aluminum CNC machining center

- Milling machine

- CNC machining center with pallet changer

- Compact CNC machining center

- 3-axis milling machine

- Machining center for the automobile industry

- CNC machining center with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.