- Products

- Catalogs

- News & Trends

- Exhibitions

Type 4 safety light curtain ULCT seriesmultibeamthrough-beamIP65

Add to favorites

Compare this product

Characteristics

- Function

- type 4 safety

- Type of beam

- multibeam

- Configuration

- through-beam

- Protection level

- IP65

- Other characteristics

- hand protection, infrared, finger protection, compact, with integrated controller

- Operating range

Max.: 1,500 mm

(59.1 in)Min.: 100 mm

(3.9 in)

Description

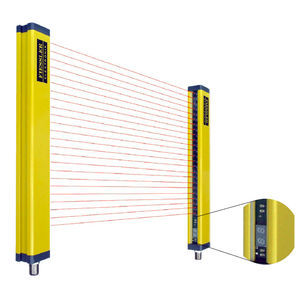

ULCT/BLCT safety light curtains each comprise two components:

Light transmitter and light receiver.

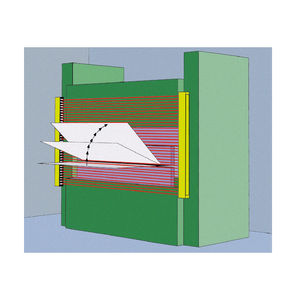

The clearance between these two components and the installation height determine the width and height of the protective field (Figure 5/1). Modular design permits realization of protective field heights ranging from 100 mm to 1500 mm in 100-mm steps.

The transmitter generates infrared light beams in rapid pulses. These parallel light beams are analyzed by two single-chip controllers in the transmitter.

The beam spacing determines the resolution. If an object enters the protective field, i.e. if at least one light beam is interrupted, the receiver's two outputs stop the machine or prevent it from starting, thus avoiding hazards.

In the restart with interlock operating mode, the machine can only be restarted by means of the start button once the protective field has been cleared again.

Properties

Integrated control-unit with contactor control and restart can be programmed without a PC

Contactor/valves directly connectablly, switching capacity 0,5A/24V

Smallest safety distances by short response times 4 ms to 29 ms, depending of the protection high

Finger and hand protection with up to 5m protective width(resolution 14 mm and 30 mm)

Protection heights from 100mm to 1500 mm in steps of 100 mm

Microcontroller monitoring of the safety functions (self-monitored)

Semiconductor outputs with short-circuit and crossconnection monitoring

Integrated self-diagnosis with a fault indication by 7-digit display

Direct connection via M12 connector

Compact design 25 x 35 mm w/ flexible fastening by tenon blocks and protection category IP 65

Catalogs

Product Catalog

172 Pages

Related Searches

- Light barrier

- Multibeam light barrier

- Vinyl mat

- Safety light barrier

- Through-beam light barrier

- Waterproof light curtain

- IP65 light barrier

- Infrared light barrier

- Ribbed matting system

- Hand protection light curtain

- Body protection light barrier

- Compact light barrier

- Measuring light curtain

- Finger protection light curtain

- Muting light curtain

- Single-beam light barrier

- Metal mat

- Pressure-sensitive safety mat

- Access control light curtain

- Aluminum mat

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.