- Products

- Catalogs

- News & Trends

- Exhibitions

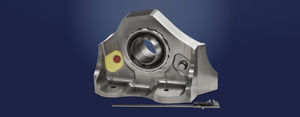

Titanium milling machining for aeronauticsfor metal fabricationmedium series

Add to favorites

Compare this product

Characteristics

- Treated material

- titanium

- Applications

- for aeronautics, for metal fabrication

- Production method

- small series, medium series, large series

- Other characteristics

- CNC, precision, 5-axis, 3-axis, 4-axis

- Certifications

- EN 9100, ISO 9001

Description

Figeac Aero has recognised expertise in the industrialisation and management of complex component part production series. The Company's many machines are among the best performing in Europe and use the most advanced high-speed machining technologies to ensure competitiveness in a global market.

Figeac Aero has organised its production into profit centres to provide the quality, responsiveness, deadline management and expertise demanded by its customers. The sites are equipped with specialised machining units for:

Aluminium structural parts,

Hard metal structural parts,

Engine and precision parts.

Continuously improving machining skills

Figeac Aero has acquired expertise on the most efficient machines for each family of products to ensure record production times (3, 4 and 5-axis machining centres, lathe and milling machines, vertical lathes, profile machining centres, specialised sheet metal work, forming machines).

Figeac Aero is spreading its know-how to sites around the world to provide a consistent level of local service to customers. Figeac Aero Group operates over 300 numerical control machines enabling it to produce parts ranging from small fittings (26mm) to aircraft spars over 20 metres in length designed for extreme tolerance levels.

The Company meets the control and quality standards of customers in compliance with ISO 9001 Version 2008 and EN9100 norms.

Related Searches

- Machining service

- Milling machining

- Metal milling machining

- CNC milling machining

- ISO machining

- ISO 9001 milling machining

- Precision milling machining

- Turning machining

- Metal turning machining

- CNC turning machining

- Small series milling machining

- Medium series milling machining

- Precision turning machining

- ISO 9001 turning machining

- 5-axis milling machining

- 3-axis milling machining

- Aluminum milling machining

- Steel milling machining

- Large series milling machining

- Aeronautic milling machining

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.