Explosion vent panel 1.23 - 1.81 PSIG | Flex-V®

Add to favorites

Compare this product

Description

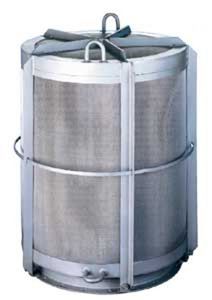

The exciting Flex-V re-closing explosion vent is a high performance device designed to protect industrial process equipment against the damaging effects of dust and gas explosions. Unlike traditional explosion venting, the Flex-V explosion panel returns to its original position at the end of the venting process, re-covering about 90% of the vent relief area. The unique Flex-V design allows fire-fighting agents the opportunity to effectively control fire situations, and for many industrial applications, offers significant benefits over non-reclosing explosion vents:

* Venting process is shortened, reducing the risk of secondary explosions

* Space is re-confined, allowing more efficient use of fire-fighting agents, such as Fike's ProInert (inert gas) and CO2 fire suppression systems

* Can open inward, offering protection against vessel collapse due to vacuum pressure

Other key Flex-V re-closeable explosion vent features:

* Integrated frame for easy installation and maintenance

* Insulation reduces condensation and acoustic emission levels, and avoids energy loss

* Non-fragmenting opening offers additional safety

* Optional burst indicator available

Catalogs

No catalogs are available for this product.

See all of Fike‘s catalogsRelated Searches

- Rack-mount server

- Digital recorder

- Smoke detector

- Video server

- Control module

- Network recorder

- Fire extinguishing system

- NVR recorder

- Explosion vent panel

- Networked camera server

- Alarm control panel

- Explosion vent

- Fire alarm control panel

- Flameless explosion vent

- Fire alarm system

- Explosion isolation system

- Water-based fire extinguishing system

- Explosion suppression system

- CO2 fire extinguishing system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.