In-line filling machine Synchromat seriesautomaticbottlecontainer

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- bottle, container, can

- Product applications

- liquids

- Type

- piston, linear, in-line

- Throughput

Max.: 200 p/min

Min.: 0 p/min

- Volume

Max.: 1,100 ml

(37.2 US fl oz)Min.: 1 ml

(0 US fl oz)

Description

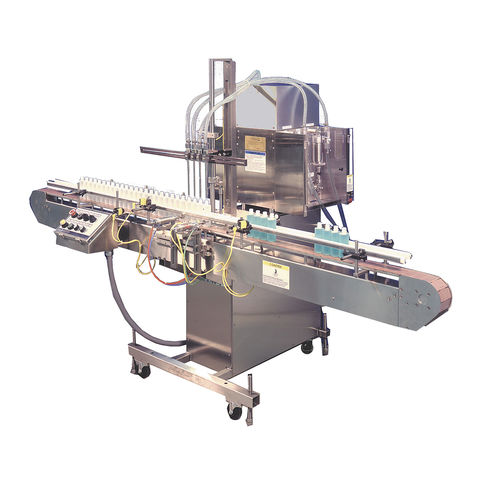

Synchromat Filling Machine

•Fill accuracy of ±/- 1% or better

•Horizontal bottle centering system

•Programmable controller

•Scalable filling stations

•Fallen bottle sensor at infeed

•Dispenses free flowing to high viscosity liquids

•Design allows you to expand from 2 to 20 nozzles as production demands increase

•Optional multi-stroke system extends range beyond one Liter

The FILAMATIC Synchromat in-line filling system provides automated, high-speed liquid filling and integrated handling for small to large-sized containers, all within a heavy-duty stainless-steel frame. Consisting of automated, diving nozzles with optional bottom-up servomotor driven dispensing, multiple indexing technologies to suit varying container profiles, an integrated, 8’ (or longer) conveyor and a highly- expandable pump drive system, this turnkey filling system is able to grow with the demand for your product. With the expandable drive-bar assembly, the Synchromat is capable of single-stroke filling of containers up to 1100 mL (37 oz) in size. At optimal conditions, total output rates as high as 200 bottles per minute are possible, with pump quantities expandable to drive upwards of 20 simultaneous filling stations. Thanks to the scalable nature of the drive system, a unit that begins with two pump stations could one day be retrofitted to run upwards of ten or even 20 stations. A multi-stroke operation mode makes filling possible for even larger container sizes without additional operator intervention thanks to the programmable on-board controller.

For maximum user-friendliness, a digital HMI touchscreen provides easy access to all functions for troubleshooting, maintenance, and observation.

VIDEO

Catalogs

Filamatic Synchromat

2 Pages

Related Searches

- Automatic filler

- Liquid filler

- Bottle filler

- Food product filling machine

- Volumetric filler

- Semi-automatic filler

- Container filler

- Piston filler

- Automatic capper

- Weight filler

- Bottle capper

- High-speed filler

- Can filler

- Filling and capping machine

- Linear filler

- Multi-container filler

- Automatic filler and capper

- Filler and capper

- Glass bottle filler

- Chemical product filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.