Monobloc filler and capper Fusion2™rotarypistonperistaltic pump

Add to favorites

Compare this product

Characteristics

- Type

- monobloc, rotary, piston

- Product applications

- peristaltic pump

Description

•Small footprint

•All stainless steel construction

•Data output with remote accessibility

•Recipe driven changeover

•Complete validation documents available, (FRS, DDS, FAT/SAT & IQ/QQ)

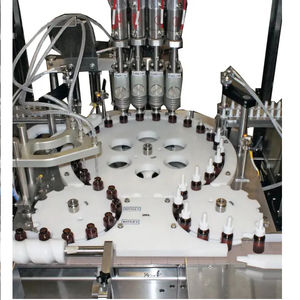

FILAMATIC’s Fusion2™ is a proven breakthrough in Monobloc technology; this new intermittently operated system can be offered as a 2 or 3 function Monobloc and can accommodate everything from microliters to 250 ml containers and offers an output up to 60 containers per minute. It is the ideal system for a laboratory to medium-scale production.

Within this Monobloc, you can perform filling, tip/stopper placement, as well as cap/over-capping. The most notable new feature or lack of will be the extremely cumbersome large remote control panel that is NO LONGER necessary. The Fusion2’s design incorporates this overall electrical need in a very safe, efficient and cost-effective way. When installing the Fusion2 Monobloc in your facility, you will only need to connect the power and air lines – that’s it! For some applications, you may wish to incorporate vibratory bowls for pre-sorting tips and caps. However, these sorting bowls are easy-to-setup, freestanding, and can be quickly positioned within your existing floorplan.

It is designed to easily accept HEPA filtration units and can be equipped with a variety of servo-driven metering systems including piston pumps, peristaltic and rotary piston pumps. Production rates can reach 60 cpm and combined with a smaller footprint with a lower cost point makes the Fusion2 the right choice for many liquid filling and capping projects.

Highlights and options of the Fusion2 include:

•Compact design

•Good machine accessibility

VIDEO

Catalogs

No catalogs are available for this product.

See all of Filamatic‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Bottle filler

- Food product filling machine

- Volumetric filler

- Semi-automatic filler

- Container filler

- Piston filler

- Automatic capper

- Weight filler

- Bottle capper

- High-speed filler

- Can filler

- Filling and capping machine

- Linear filler

- Multi-container filler

- Automatic filler and capper

- Filler and capper

- Glass bottle filler

- Chemical product filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.