Automatic filling system ProLINE™ for food productsfor chemical productsoil

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product applications

- for food products, for chemical products, oil, for cosmetic products

- Type

- pneumatic

- Other characteristics

- pneumatic

Description

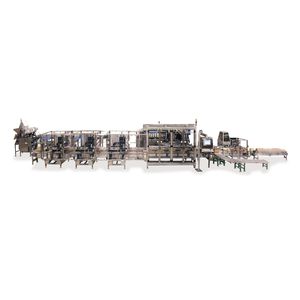

The ProLINE™ automatic filling system is Filamatic’s latest total filling line solution with all the accoutrements to successfully get your product to the market.

The ProLINE system is a complete Inline fill-cap-label solution. Now you can have a full, quality and 100% USA made turnkey system at an affordable price. With unheard of lead times 4 weeks or less for a full system, the ProLINE is ideal for medium to higher speed applications across a wide-range of industries: from pharmaceuticals, cosmetics, and thick personal care products, to tinctures, e-liquids, specialty chemicals, as well as food-grade oils.

Most importantly, the modular design allows you to be in complete control of your production process; pick and choose the packaging components that fit your budget and production needs at the time of purchase, while allowing for future scaling as budgets or demands arise. In addition, this type of design affords you the ability to arrange it to fit within the confines of your facility. If existing equipment or room sizes don’t allow for longer, straight conveyor runs, we can work with you to layout any number of bends or snaking arrangements to suit; the possibilities are nearly endless.

In addition to the EconoFIL filling unit and the standalone, enclosed CT-100 or CT-200 pneumatic indexed capping systems, FILAMATIC’s ProLINE system is often accompanied with unscrambling and accumulation tables, different length conveyors, labeling solutions, batch-code printing options, and shrink sleeve banding systems with heat tunnels. For maximum flexibility, all of these subsystems can be purchased individually or in an integrated package.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Filamatic‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Bottle filler

- Food product filling machine

- Volumetric filler

- Semi-automatic filler

- Container filler

- Piston filler

- Automatic capper

- Weight filler

- Bottle capper

- High-speed filler

- Can filler

- Filling and capping machine

- Linear filler

- Multi-container filler

- Automatic filler and capper

- Filler and capper

- Glass bottle filler

- Chemical product filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.