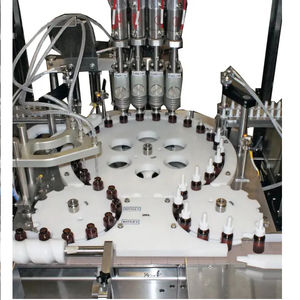

Automatic filler and capper Monobloc seriesfor liquidsmonoblocintermittent-motion

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product applications

- for liquids

- Type

- monobloc

- Other characteristics

- intermittent-motion

Description

•Highly flexible

•All stainless steel construction

•Quick and easy tool-less changeover

•Handles dropper tips and eye droppers

•Servo cap torqueing with feedback

FILAMATIC’s® popular Monobloc series is a single index system capable of performing a wide range of tasks such as: sorting, feeding, nitrogen flushing, filling, plugging, stopping, crimping, capping, labeling, and accumulating. Additional processes, e.g. induction sealing, tamper-evident banding, etc. can be easily coupled with the Monobloc series. Our Monoblocs can accommodate everything from microliters to 500ml containers and offers an output up to 60 containers per minute. The Monobloc serves a variety of industries but is ideal for the Pharmaceutical, Diagnostic, Biotech, Animal Health & Cosmetic industries because it is engineered to perform multiple tasks within a compact footprint. Common containers that are supported by Filamatic Monoblocs include vials, cryovials, microtubes, different types of nasal spray containers, airless pumps, Boston round glass and plastic containers.

The Monobloc series can be equipped to support a variety of servo driven meter systems including piston pumps, peristaltic, and rotary piston pumps allowing you to handle a wide range of viscosities from free-flowing to viscous products. Optional HEPA filtration systems can also be incorporated to provide positive pressure airflow within the machine environment.

All FILAMATIC Monoblocs are digitally controlled with menu-driven programs that electronically adjust operating parameters for quick and easy tool-less changeovers.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Filamatic‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Bottle filler

- Food product filling machine

- Volumetric filler

- Semi-automatic filler

- Container filler

- Piston filler

- Automatic capper

- Weight filler

- Bottle capper

- High-speed filler

- Can filler

- Filling and capping machine

- Linear filler

- Multi-container filler

- Automatic filler and capper

- Filler and capper

- Glass bottle filler

- Chemical product filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.