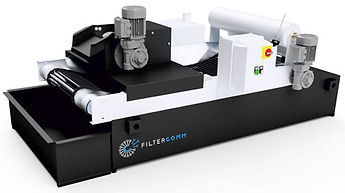

Ideal for the filtration of both emulsions and neat oil. Grade of filtration ranges from 50 to 10 micron, depending on the type of filter fabric used.

Gravity flat bed paper filters can be combined with MAGDISK magnetic separators to achieve more efficient filtration grades of industrial coolants and reduce filter fabric consumption.

Dirty coolant is conducted into the flat bed filter's coolant inlet and is distributed along the underlying filter fabric, which in turn retains the pollutant particles and allows the clean coolant to fall inside the clean coolant containment tank.

The filter fabric progressively collects the pollutants until it is clogged; once the coolant cannot pass through the filter fabric, the liquid level rises and lifts a float; the float activates advancement of the carpet which substitutes the used filter fabric with new one.

Exhausted filter fabric is collected inside a small tank for disposal and the clean coolant can be transferred back to the machine tool by means of a pump.

A wide range of flat bed paper filter models to choose from. The Gravity range allows you to match the right coolant filtration system to your machine tool, avoiding inefficiency and excessive consumptions due to over- or under-dimensioned filtration systems.