- Power Transmission - Mechanical components

- Bearing and Linear Guide

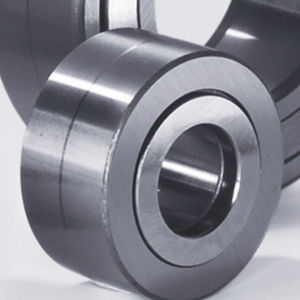

- Radial cam follower

- Findling Wälzlager GmbH

Axial stud type track roller LR-2...-NPP(U)radialsingle-rowzinc

Add to favorites

Compare this product

Characteristics

- Specifications

- axial, radial, single-row

- Material

- zinc

Description

In track rollers and stud-type track rollers, balls are used as rolling elements and, like cam followers (with needles as rolling elements), they have a reinforced outer ring that serves as a running area and preferably has a spherical design so that no edge stresses arise under high loads.

Track rollers do not have a threaded end and are instead installed on a suitable axle. In addition to radial forces, they can also absorb axial forces. They are available in single-row and double-row designs..

Stud-type track rollers already have a threaded end and comprise a double-row ball bearing.

Related products: Track rollers with a raceway profile

Inadequate sealing can allow external environmental conditions to have an extremely negatively impact on running characteristics and thus a bearing’s service life. For this reason, bearings must be protected by seals.

At the same time, seals also prevent lubricants from leaking.

NPP/NPD/KRD: integrated contact seals; alternative designation: 2RS, DRS

KDD: integrated dust shields with a gap for low-friction motion with a limited protective effect; alternative name: ZZ oder 2Z

Note: The NUTR series has a labyrinth seal due to a seal washer sheet.

Track rollers are usually lubricated for life. The LR-5... series has lubrication hole in its inner ring that can be used to add lubricant.

Coated track rollers

The manufacturer Schaeffler offers its products with its special "Corrotect" coating. We also supply designs with a zinc-iron (ZnFe) and a zinc-nickel coating.

Catalogs

No catalogs are available for this product.

See all of Findling Wälzlager GmbH‘s catalogsRelated Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Plain bearing

- Axial rolling bearing

- Single-row bearing

- Track bearing

- Metal plain bearing

- Deep groove ball bearing

- Double-row bearing

- Precision bearing

- Rod end

- Cylindrical roller rolling bearing

- Steel wheel type roller

- Cage assembly bearing

- Tapered roller bearing

- Angular-contact bearing

- Self-lubricating plain bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.