- Power Transmission - Mechanical components

- Bearing and Linear Guide

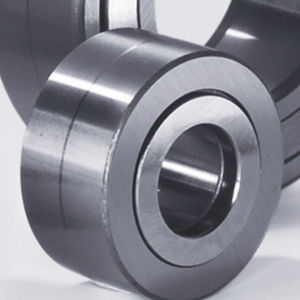

- Metal cam follower

- Findling Wälzlager GmbH

Metal cam follower KR

Add to favorites

Compare this product

Characteristics

- Material

- metal

Description

Cam followers have a reinforced outer ring that serves as a running area and preferably has a spherical design so that no edge stresses arise under high loads. Unlike yoke type track rollers, cam followers have a threaded end for simple installation. For simplified installation, there are designs with a slot for a screwdriver or a hexagon socket. Designs with an eccentric on the shaft allow the outer ring race to be adjusted in relation to the raceway.

PP/2RS: integrated contact seals.

Cam followers can be relubricated in various ways. There are different designs depending on the manufacturer. Designs with a hexagon socket (suffix SK or 2SK) usually have an integrated front lubrication nipple or an additional one at the rear. In addition to this, cam followers can be relubricated in the shaft by means of a central lubrication system via a lubrication groove with a lubrication hole.

Caution: Designs with an eccentric ring cover the lubrication groove with a lubrication hole in the shaft and can as a result only be relubricated from the front or rear.

Note:

As standard, ABEG® needle-roller bearings are supplied ungreased and only preserved. However, some other manufacturers provide them with a lithium complex soap grease ex works. Please ask your dealer or specify the design you want when ordering.

Designs with a V in their name are full complement designs. Full complement designs have a significantly higher load rating. However, this reduces the maximum speed.

Catalogs

No catalogs are available for this product.

See all of Findling Wälzlager GmbH‘s catalogsRelated Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Plain bearing

- Axial rolling bearing

- Single-row bearing

- Track bearing

- Metal plain bearing

- Deep groove ball bearing

- Double-row bearing

- Precision bearing

- Rod end

- Cylindrical roller rolling bearing

- Steel wheel type roller

- Cage assembly bearing

- Tapered roller bearing

- Angular-contact bearing

- Self-lubricating plain bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.