- Products

- Catalogs

- News & Trends

- Exhibitions

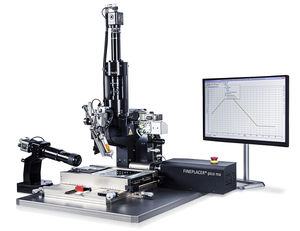

Sub-micron die bonder FINEPLACER® femto 2fully-automaticautomatedhigh-accuracy

Add to favorites

Compare this product

Characteristics

- Options

- fully-automatic, sub-micron, automated, high-accuracy

Description

Automated Prototype2Production Bonder

The FINEPLACER® femto 2 is a fully-automated die bonder with a placement accuracy of 0.5 µm @ 3 sigma. A complete machine enclosure allows very demanding applications in a controlled environment. Fully protected from external influences, the system stands for highly stable assembly processes with the focus on maximum yield.

The new generation of the femto platform adds numerous innovations to the proven technical basis. This includes the cutting-edge FPXvisionTM. Combined with a refined pattern recognition, this all-new Vision Alignment System opens up a new dimension of application flexibility and accuracy. IPM Command, the fully revamped FINEPLACER® operating software, supports a consistent, ergonomic and clearly structured process development.

Depending on the requirements, the modular FINEPLACER® femto 2 can be individually configured and retrofitted at any time to support new applications and technologies. This makes the system a perfect tool and reliable companion as applications migrate from product development to production. It covers the entire workflow of inspection, characterization, packaging, final test and qualification in semiconductor, communications, medical and sensor technologies.

Highlights

- Placement accuracy 0.5 µm @ 3 sigma

- Fully-automated operation

- Manual operating routines available

- Controlled process environment with cleanroom quality

- Operator protection from emissions (lasers, UV sources, gasses)

- Full process access and quick process setup

- FPXvisionTM: maximum resolution across large field of view

- Ergonomic operating concept with touch screen interface

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.