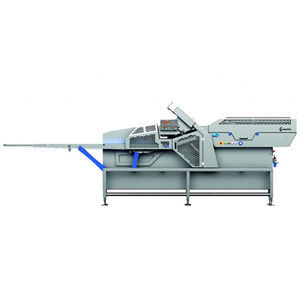

Meat slicer SliceFil-620 / 625automaticcircular bladestainless steel

Add to favorites

Compare this product

Characteristics

- Food product

- meat

- Operating mode

- automatic

- Cutting tool

- circular blade

- Material

- stainless steel

- Installation

- floor-standing

- Orientation

- vertical

- Throughput

600 p/min

- Slice thickness

Max.: 100 mm

(3.9 in)Min.: 0.5 mm

(0 in)- Cutting height

150 mm

(6 in)- Weight

1,000 kg, 1,700 kg

(2,205 lb, 3,748 lb)

Description

The range of automatic SliceFil slicers are noted for their high performance and range of use. They are indicated for industries with large production of cold meats, ham and cheese. Product loading is done manually or automatically depending on the customer needs. The product is supported by clamps that move the product toward the circular blade and cutting the product with great precision placing it in stacked portions or staggered batches in an output belt that is forward synchronized.

Features:

Heavy duty construction made of AISI-304 stainless steel.

Machine made according to the European Directive 2006/42/CE.

This slicer is ideal for cutting and stacking cured and cooked sausage, fresh meat and cheese.

Portioner conveyor-belt of 250mm length, separator conveyorbelt of 250mm length with automatic vertical tilt up to 70mm high.

Automatic and pneumatic clamp grip of product with product sensor.

Vertical and lateral pneumatic pusher-plates with pressure adjustable from the control panel.

Product presentation: stepped, stacked, stepped-stack, individual slices, “shaved-meat”, oval shapes, one row beside another,different programmable figures, etc. The number of slices in each group may be varied according to requirements, as well as the length of the portions and the separation between portions.

Cutting system, both circular and orbital rotation, with independent motors and independent speed control through the control panel.

Easy adjustment of all settings using the touch sensitive screen

of 15”.

Catalogs

No catalogs are available for this product.

See all of FINOVA‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.