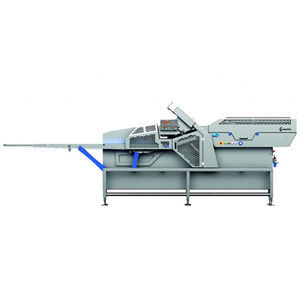

Ham slicing machine Slicefil-300sausageautomaticcircular blade

Add to favorites

Compare this product

Characteristics

- Food product

- ham, sausage

- Operating mode

- automatic

- Cutting tool

- circular blade

- Electric powered

- 230V single phase

- Material

- stainless steel

- Other characteristics

- compact

- Throughput

300 p/min

- Slice thickness

Max.: 50 mm

(2 in)Min.: 0.5 mm

(0 in)- Engine power

2.8 kW

(3.8 hp)- Length

2,651 mm

(104 in)- Width

873 mm

(34 in)- Height

1,730 mm

(68 in)- Weight

410 kg

(904 lb)

Description

The new automatic slicer SliceFil-300 stands out for its simplicity of use, compact dimensions, high performance and variety of use, its use indicated in industries of medium production of cured or cooked sausages, ham and cheese. The product is loaded manually and is supported by a clamp. The cut is made through a circular type blade, by cutting the product with great precision and placing it in stacked portions, staggered batches, or other presentations, on the synchronized advance output belt.

Features:

Loading of the product on a conveyor belt that prevents damage due to friction during slicing.

Manually operated universal product gripper.

Cutting system with circular type blade with independent regulation of the speed of rotation and orbit.

Upper and side product pressers with pneumatic adjustment and adjustable pressure.

Gate for product loading with gas pistons.

The drive of the machine is done by servomotors.

Electromechanical security systems in gates and protections.

The number of slices in each portion can vary according to requirements, as well as the length of the portions.

Up to 50 mm stacking height of portion.

Fully open and hygienic design.

Quick access to the main functional elements to facilitate washing and maintenance of the machine.

Robust construction and made of AISI-304 stainless steel.

Machine built in accordance with the European Directive 2006/42/CE.

Easy adjustment of all cutting parameters through the integrated 7” touch screen with intuitive menus and icons.

Allows storage of up to 50 recipes.

Includes output conveyor belt for manual feeding of 800mm length portions.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FINOVA‘s catalogsRelated Searches

- Slicer

- Automatic slicer

- Meat grinder

- Meat slicer

- Stainless steel meat grinder

- Floor-standing slicer

- Automatic meat grinder

- Meat meat mincer

- Stainless steel slicer

- Meat kneader

- Circular blade slicer

- Industrial bowl cutter

- Meat forming machine

- Portioning machine

- Automatic meat forming machine

- Meat tumbler

- Stainless steel meat kneader

- Classic meat mincer

- Vacuum meat tumbler

- Automatic portioning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.