- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Miniature cable assembly power

Add to favorites

Compare this product

Characteristics

- Other characteristics

- power, miniature

Description

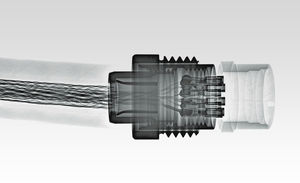

Cabling miniature and dense connectors is extremely challenging and requires special technical know-how and specific tooling, assembly techniques and testing methods, well mastered by our operators. Miniaturization processes pertain to the entire chain of the cabling design and manufacture, including:

• Part alignment on both the plug and receptacle

• Bend relief cutting and cable jacket stripping

• Conductor back trimming and stripping

• Soldering, braid shielding, insulator tube and back nut potting

• O-ring and boot bend relief fixation, etc.

Leverage our expertise in miniaturization to design compact, lightweight and small-footprint cable assemblies that fulfill the shape, size, weight and power (SWaP) requirement of your device and electronic ecosystem.

Catalogs

No catalogs are available for this product.

See all of Fischer Connectors‘s catalogsRelated Searches

- Electrical connector

- Data electrical connector

- Electrical power supply connector

- Metal electrical connector

- Round electrical connector

- Female electrical connector

- Screw-in electrical connector

- Polymer connector

- IP67 electrical connector

- Circular electrical connector

- Industry connector

- Cable connector

- Cable assembly

- Current connector

- IEC electrical connector

- Coaxial electrical connector

- Power connector

- IP68 electrical connector

- Hermetic connector

- Crimp electrical connector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.