Palletizing software analysispackingprocess

Add to favorites

Compare this product

Characteristics

- Function

- analysis, palletizing, packing

- Applications

- process

- Type

- automated

Description

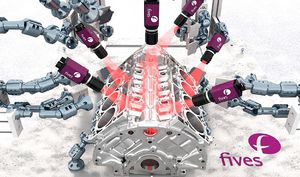

Fives has developed a seamless software suite for mixed-case palletizing. Our software calculates optimal pallet stacking to ensure the reliability of the palletization process and minimize the risk of product damage during transport.

Automated palletizing is becoming a must for warehouses and plants that manage large numbers of stock keeping units (SKUs) and highly customized orders. Fives’ intelligent technology for automated palletizing optimizes packing and productivity. Key benefits include:

• Improved working conditions for operators

• Higher order accuracy

• Less products damages during transport

• More efficient use of space

• Optimized shelf restocking

Fives’ palletization algorithm calculates optimum stacking of mixed-case pallets. Our software considers a number of factors :

• Products characteristics (dimension, shape and weight).: Large and heavy cases are loaded on the bottom of the pallet and small and light units are loaded on top. Considering product characteristics is indispensable to avoid product damage and ensure pallet stability during palletizing and transport.

• Shelf restocking sequences: to optimize in-store operations and logistics costs.

• Pallet density: to reduce volume and ensure products stability

After this analysis, our SU® Warehouse Management System translates the data into instructions for the palletizing robots.

Catalogs

No catalogs are available for this product.

See all of Fives Cinetic SAS‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Online software

- Real-time software solution

- Design software solution

- 3D software solution

- Monitoring software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Automated software

- Development software

- Engineering software

- Test software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.