Digital twin software simulationengineeringdesign

Add to favorites

Compare this product

Characteristics

- Function

- simulation, engineering, design, test, automation, digital twin

- Type

- 3D, real-time, automated

Description

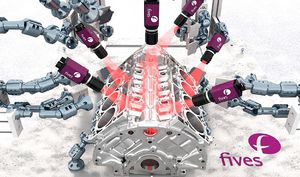

Fives leverages digital twin technology to mirror physical systems and enhance operations.

GET A DIGITAL MODEL OF YOUR SYSTEMS

Production lines and warehouses complexity is continuously increasing with more and more sophisticated equipment and systems communicating with one another. Tasks that were performed manually are now fully automated.

This complexity is combined with the need for reducing project time to market to improve overall project ROI.

Digital twins enables Fives to design, implement and commission more complex systems in a shorter time.

Mirroring automated system in a digital environment drives performance throughout the installation lifecycle. Operators can simulate production line or warehouse performance and precisely, quickly assess the impact of any change in equipment, software or production plans. The ability to test with no risk real-world scenarios in the virtual environment will prevent you to unnecessarily disturb your operations and spend money.

Fives’ Smart Automation Solutions Division’s Digital Twin solution is a digital, 3D and real-time representation of your system and workflows. It is the perfect simulation model to enhance performance throughout the system lifecycle. Our digital twin technology is ideal for a wide range of activities, from engineering to project execution, operations and maintenance.

Catalogs

No catalogs are available for this product.

See all of Fives Cinetic SAS‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Online software

- Real-time software solution

- Design software solution

- 3D software solution

- Monitoring software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Automated software

- Development software

- Engineering software

- Test software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.