- Robotics - Automation - Industrial IT

- Service Robotics

- Cleaning robot

- Fives Cinetic SAS

Cleaning robot

Add to favorites

Compare this product

Description

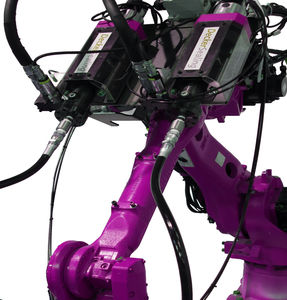

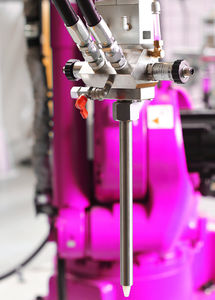

Our robotized solution comprises a cleaning and priming head so that both operations can be carried out in one station. The equipment includes the very soft cotton pad for cleaning and brush for applying the primer. You can select the robot that best suits your existing setup. You can also add a vision control system if desired, so that you can confirm that the primer has been applied correctly.

Dosing of the cleaning agent and primer is carefully controlled with peristatic pumps, manually adjusted to match the speed of your assembly line. The pump is located directly on the application head, ensuring you use just the right amount of cleaning agent or primer and there is no waste. Maintenance of this system is simple, with just one small pipe to be changed every once in a while.

Catalogs

No catalogs are available for this product.

See all of Fives Cinetic SAS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.