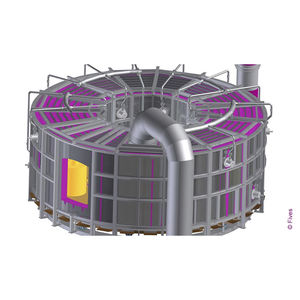

Chamber furnace PF tunnelreheatinggas

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber, tunnel

- Function

- reheating

- Heat source

- gas

- Other characteristics

- for billets

Description

This simple mechanical system ensures the billets, slabs, blooms and beam blanks moving through the furnace are always well aligned. This, together with the near-total lack of cooled elements inside the heating chamber, makes it highly energy efficient and gives you very low operating costs. It also requires the lowest CAPEX of any type of furnace.

Our low-fuel consumption design gives you a high return on investment and a reduced maintenance cost.

New lining patterns to reduce heat losses

Solid hearth design with or without skids

Designed to heat products made of carbon, alloy, stainless or special steels, the pusher furnace is also fuel-efficient and can utilize fuels including natural gas, fuel oil, COG, BFG and mixed gas thanks to the state-of-the-art AdvanTek® burners.

Top and bottom-fired pusher furnaces for billets, slabs, blooms and beam blanks 60-300 t/h

You can also customize the charging and discharging machines according to the application and layout – and even save time by opting for a prefabricated installation for ultra-fast start-up.

Stein Reheating Pusher Furnace (PF): high efficiency, low cost heating solution

Stein Reheating PF is a conventional solution for heating products that works by pushing products through the combustion chamber. The simple mechanical system and near-total lack of cooled elements inside the heating chamber ensure the pusher furnace offers high efficiency and very low operating costs.

Catalogs

No catalogs are available for this product.

See all of Fives DMS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.