Tunnel furnace Stein WBFreheatingelectric

Add to favorites

Compare this product

Characteristics

- Configuration

- tunnel

- Function

- reheating

- Heat source

- electric

Description

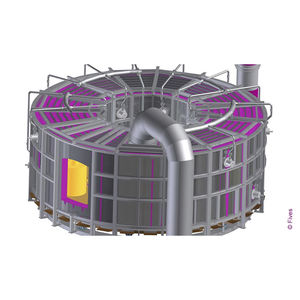

The Stein Reheating Walking Beam Furnace (WBF) – a cost-effective walking beam furnace with proportional control – is designed to reheat long and flat products.

The furnace is suitable for reheating billets, blooms, beam blanks and slabs at throughput rates from 60 up to 500 t/h and for products weighing up to 67 tons. This heavy-duty equipment can even be prefabricated for quick and easy installation. Benefits include:

Compatible with all fuel types: NG, fuel oil, COG, BFG, mixed gas, etc.

Reduced fuel consumption thanks to AdvanTek® burners

Best temperature distribution in the product

Mechanics installed away from heat for less maintenance and longer life.

Stein Reheating Walking Beam Furnace (WBF) is heavy-duty equipment, customized to requirements.

Fives’ range of Stein Reheating WBF - conventional walking beam furnaces - is designed to reheat long and flat products efficiently and effectively. This equipment is tailored to customer requirements to offer the optimum solution for your application. Prefabrication technology enables quick and easy installation.

Stein Reheating WBF is suitable for reheating billets, blooms, beam blanks and slabs at throughput rates from 60 up to 500 t/h and for products weighing up to 67 tons.

Utilized in the production of carbon, alloy, stainless or special steels, these heavy-duty furnaces incorporate:

Patented double tube skid design to minimize losses and shadow effect

Customized charging and discharging machines, according to the application

Very low scale formation

All types of fuels (natural gas, fuel oil, COG, BFG, mixed gas, etc.)

Reduced consumption due to AdvanTek® burners

Catalogs

No catalogs are available for this product.

See all of Fives DMS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.