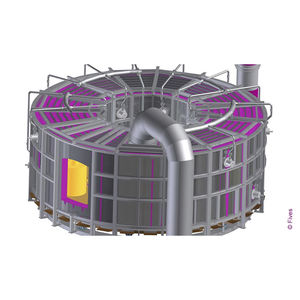

Chamber furnace CELESreheatinginduction

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- reheating

- Heat source

- induction

Description

Fives’ solution for long products incorporates a Stein reheat furnace with CELES high-flux inductors for sizable cost & energy savings and improved product quality.

Fives has developed a new hybrid solution combining a gas-fired Stein reheating furnace and a high-flux CELES CELINE inductor. This unique concept enables the billet to be reheated quickly even while the furnace is operated at a lower temperature thanks to the installation of a high-flux inductor at the furnace discharge outlet. Maintenance requirements are minimal due to the absence of refractory and an adequate thermal and mechanical protection.

The reheating inductor ensures the billet is heated at a continuous temperature and reduces skid marks, thus improving production quality.

The lower operating temperature of the furnace also offers the following benefits:

Reduction of maintenance costs, i.e. extended lifetime of refractory and unloading rolls

Reduction of scale formation, as the residence time at high temperature is drastically diminished

Minimized NOx emissions

Catalogs

No catalogs are available for this product.

See all of Fives DMS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.