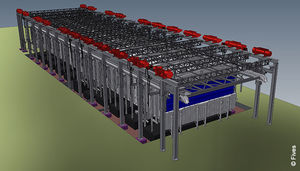

Continuous galvanizing line NeoKoil® CGL

Add to favorites

Compare this product

Characteristics

- Options

- continuous

Description

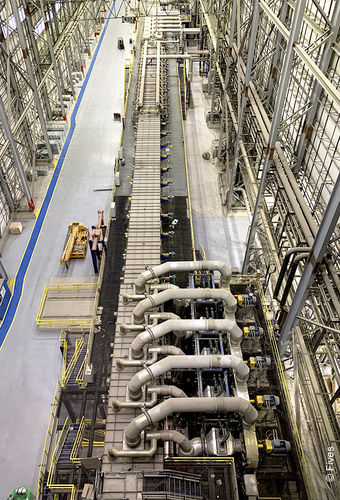

Utilizing our grade development & coating process know-how, smart tools and advanced equipment design we have delivered numerous strip processing lines with a horizontal furnace producing steel grades from building to automotive quality, from compact lines to high-speed lines.

Key technologies

NeoKlean® system – A degreasing system utilizing a combination of hydro, chemical and mechanical processes. An electrolytic NeoKlean® with improved design ensures the ultimate degree of strip cleanliness.

Thermal section – Consisting of a non-oxidizing furnace, a radiant tube furnace, a soaking furnace and a rapid cooling section. We use the AdvanTek® DFR (direct fired reducing) combustion system, which gives you homogeneous strip temperature crosswise and proven ability to process strips for automotive parts.

Aeris® after-pot – An efficient and flexible cooling system to improve strip stability by enabling the reduction of the cooling length.

Minispangle system – Aiming to minimize ‘spangles’ in galvanized strips to improve the surface quality for coating.

Skin-pass and strip leveler – Skin-pass mills coupled with strip levelers for a wide variety of annealed and galvanized steel products.

Side trimmer – Featuring a special design and blade positioning technology that offers clean and accurate edge cutting.

Fives developed NeoKoil® continuous galvanizing line (CGL) with a horizontal furnace and a companion minispangle system to produce steel grades from building to automotive applications quality. Such processing lines are cost effective and versatile.

Catalogs

No catalogs are available for this product.

See all of Fives DMS‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.