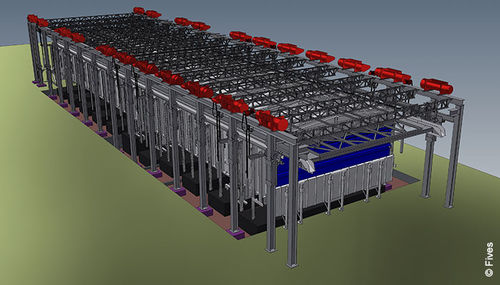

Pickling line Oxigen-X™

Add to favorites

Compare this product

Description

Surface treatment of wires, bars & tubes

Utilizing either a hydrochloric or sulfuric acid solution, oxides are readily removed. The totally enclosed system features a monorail or overpassing design, including coil drying.

The line is fully automated for maximum throughput with a process step tracking system and process monitoring to insure repeatability.

The chemical management system allows the process to adapt to each coil based on weight, material composition, surface area and treatment steps.

Long product pickling lines from Fives feature state-of-the-art technology and autonomous control for the most effective surface treatment of wires, bars and tubes. Using either an HCl (hydrochloric acid) or H2SO4 (sulfuric acid) solution to remove oxides from long products, these totally enclosed systems feature a monorail or overpassing design and coil drying. They are fully automated for maximum throughput, with a process step tracking system and process repeatability.

The chemical management system allows the process to adapt to each coil based on weight, material composition, surface area and treatment steps. It is the best design for the environment and offers the maximum protection for the operator.

Long product pickling system includes:

Chemical treatment

Dip rinse

High pressure rinse

External spray rinse

Phosphating

Containment hood

Fume collection and treatment systems

Monitoring and dosing

Fully automated material handling

Inspection

Catalogs

No catalogs are available for this product.

See all of Fives DMS‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.