- Machine-tools

- Machining Center

- 3-axis machining center

- Fives Machining

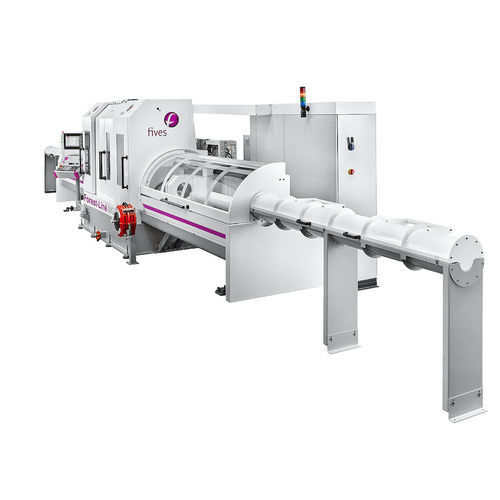

3-axis CNC machining center FOREST-LINÉ MGP™ 150universal3-spindleHSK-E50

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- universal

- Number of spindles

- 3-spindle

- Spindle mount

- HSK-E50

- Number of tool stations

- 24 tools

- Associated functions

- milling, chamfering, drilling

- Applications

- for the aerospace industry, for profiles

- Other characteristics

- high-speed, high-precision, high-rigidity, modular, automated loading/unloading

- Rotational speed

Max.: 21,000 rpm

(131,947 rad.min-1)Min.: 1,000 rpm

(6,283 rad.min-1)- Power

12 kW

(16.32 hp)

Description

The Forest-Liné MGP™150 is a modular machine capable of drilling, milling, chamfering, routing and end-machining from short and simple to long and complex aluminum extrusions.

The Forest-Liné MGP™ 150 features three active spindles and uses a patented push-pull process for continuous aluminum extrusion bar feeding.

Fast loading and unloading and a continuous machining process ensure maximum throughput and no windowing. Meanwhile, the high rigidity spindle gives you absolute accuracy, whatever the operation.

The whole process is fully automated for the utmost repeatability and safety. All machining can be done in one continuous process with no operator intervention. Easy programming makes for a user-friendly experience, while sophisticated software allows for a flexible range of chuck movement combinations.

The Forest-Liné MGP™ is also available for machining 220 x 260 mm profile sections.

Additional advantages include:

Flexible jaws, reduced tooling costs

Infinite length process

Easy tool changer

Temperature offset system

Probing system

No foundations required

Auto-reverse process

Low maintenance costs

Catalogs

Forest-Liné MGP™ 150

2 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Bridge CNC milling machine

- Precision CNC milling machine

- Horizontal CNC machining center

- Drilling CNC machining center

- Compact CNC machining center

- 24 tools CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.