Monitoring regulation system FCB Opti-Bmill™

Add to favorites

Compare this product

Characteristics

- Options

- monitoring

Description

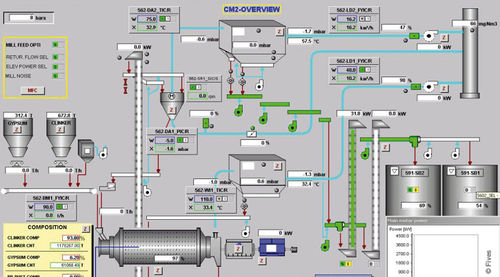

FCB Opti-Bmill™ is a modular intelligent system for on-line optimization and automated control of the ball mill grinding unit.

Integrated in the existing process control system, it controls and regulates automatically the process parameters of the mill according to the recipe and targeted fineness and based on the actual operating parameters (recirculation flow, electronic ears, absorbed power, separator air flow, elevator power…).

FCB Opti-Bmill™ system determines the theoretical production volume and adjusts automatically the circulation load and the separator speed when combined with an online Particle Size Analyzer.

The main functionalities of FCB Opti-Bmill™ are:

Pre-set of the product recipes

Optimization of the product load inside the mill

Optimization of the ball load inside the mill

Optimization and online checking of the product fineness owing to on-line Particle Size Analyzer

Customer benefits

Stabilization of the mill process

Improvement of the grinding system automation for easier operators’ work

Higher reliability of the production operations

Reduction of the energy consumption

Increased mill output

Enhanced product quality consistency and stability, in line with the targeted recipe

Technical advantages

Integration in the existing Process Control System

High reliability of the controls

Possible remote monitoring

Recording of the process data history

Combination with a Continuous On-Stream Mineral Analyser (COSMA™) for enhanced product quality

Catalogs

No catalogs are available for this product.

See all of Fives‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.