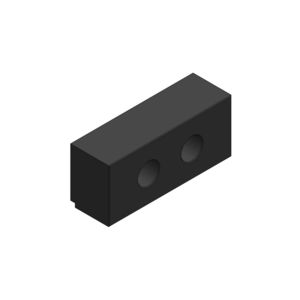

Mechanical clamp CP125 seriesworkpiecealuminumsteel

Add to favorites

Compare this product

Characteristics

- Type

- mechanical

- Applications

- workpiece

- Other characteristics

- steel, aluminum, machinable

Description

These clamps hold workpieces on the ID or OD using machinable jaws (available separately). For OD clamping, the aluminum jaws can be machined to custom fit the workpiece. For ID clamping, the workpiece is placed over ID jaws, which expand outward using a tapered pin (available separately). The part repeatability is +/- 0.03 mm, and the jaw locating repeatability of +/-0.02 mm. The clamping stroke of each jaw is .3 mm for both OD and ID clamping.

The body is made from 1045 steel with an electroless nickel plated finish. The pull cylinder is made from 4115 steel, carburized-hardened with a black oxide finish. The cam cylinder is made from 4135 steel, quenched and tempered, with a black oxide finish. Jaws and tapered pins must be purchased separately.

Note: Do NOT actuate the clamp without a workpiece to avoid damaging the clamp and jaws.

Catalogs

Fixtureworks catalog

572 Pages

CLAMPS

72 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.