- Hydraulics - Pneumatics

- Valve

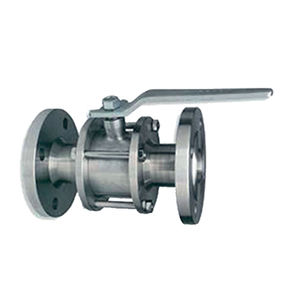

- Pinch valve

- FLAPCON VALVES AND AUTOMATION SYSTEMS CO LTD

Pinch valve AV10 pneumatically-operatedfor waterfor chemicals

Add to favorites

Compare this product

Characteristics

- Type

- pinch

- Operation

- pneumatically-operated

- Media

- for water, for chemicals, for sludge, for steam

- Body$

- threaded

- Applications

- for compressors

- Associated function

- discharge

- Other characteristics

- compact, standard

- DN

Max.: 50 mm

(1.969 in)Min.: 8 mm

(0.315 in)- Pressure

16 bar

(232.1 psi)- Temperature

Max.: 150 °C

(302 °F)Min.: -20 °C

(-4 °F)

Description

AV10 Series work depending on the internal movement of a piston supplied with air. At the end of its stroke, the piston presses on the seat seal or moves away from it letting the intercepted fluid flow or stopping it from flowing. As the seat is perfectly tight and the intercepted fluid pressures discharge on it, the necessary pressure to move the piston is completely independent of the fluid pressure. Its full bore and its improved internal dynamics allow minimum pressure losses as well.

The AV10 Series combines a pneumatic actuator and valve into one body, eliminating packing glands, actuators and mounting kits. There are no exposed moving parts, eliminating pinch points and increasing operator safety. Since the actuator is part of the valve, costs are greatly reduced when compared to standard actuated valves. Operating life has been tested to well over 1,000,000 cycles, the balanced design reduces friction and wear. The stroke is linear and parallel to the flow reducing the force to close or open the valve dramatically. The internal waterway design was designed for optimum flow characteristics.

Catalogs

No catalogs are available for this product.

See all of FLAPCON VALVES AND AUTOMATION SYSTEMS CO LTD‘s catalogsOther FLAPCON VALVES AND AUTOMATION SYSTEMS CO LTD products

valves

Related Searches

- Valve

- Hand valve

- Control valve

- Stainless steel valve

- Ball valve

- Water valve

- Pneumatic valve

- Threaded valve

- Electrically operated valve

- Valve with flange

- Regulating valve

- Stop valve

- Lever control valve

- Flap valve

- Non-return valve

- Electric valve

- Gas solenoid valve

- ISO valve

- Normally closed solenoid valve

- Valve with handwheel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.