Find your fit: Measuring 240″ by 24″ by 17.5″

Increased Speed: Spindle RPM increased for your toughest milling needs.

Customizable for you: Choose between our accessory options for a perfect fit for your workshop.

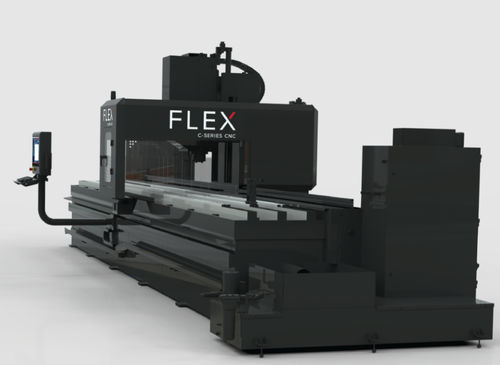

The CM-20-02 is a long-bed vertical machining center designed for flexibility. Whether single-piece or high-volume mass production, the versatility of the C-Series helps increase your productivity and overall throughput. A monobloc welded steel frame and an advanced motion control system provide the power and rigidity for enhanced performance.

Highlighted Specifications

Spindle to Table: 5″ – 22.5″

Rapid X: Max 1200 IPM

Rapid Y: Max 1000 IPM

Rapid Z: Max 300 IPM

Mobile control panel with 22” touch screen monitor

The Mobile Control Panel features a large 22-inch touchscreen monitor for clear and intuitive operation. This panel is designed to move freely along the entire length of the machine, allowing for optimal positioning based on user preference.

Through Spindle Coolant

Through spindle coolant delivers coolant directly through the cutting tool improving chip evacuation and heat control. This is ideal for deep hole drilling and when working with tough materials.

Flood Coolant

Flood coolant delivers a constant stream of coolant liquid over the entire workpiece and cutting tool. This method effectively cools a large area and flushes away chips, making it a good choice for general machining applications and situations where coolant is needed throughout the cutting zone.