Automatic tool changer with six positions allows for a streamlined workflow making your projects more efficient.

The Drill Cam Software allows users to easily customize their project needs.

The FB-50-42 is equipped with the latest generation industrial PC control, servo drivers, and servomotors produced by OMRON.

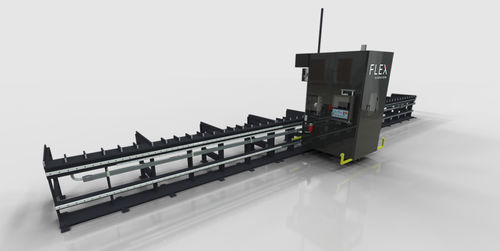

The FB-50-42 FlexBeam profile drilling center is designed for fast, accurate, and economical production of steel profiles. The machine is equipped with the latest generation industrial PC control, servo drivers, and servomotors produced by OMRON. If you drill or mill holes in a variety of steel profiles and are looking for a faster or cheaper way to do it, the FlexBeam series may be right for you.

Highlighted Specifications

Min/Max Profile Dimensions: 2" through 42"

Tap Capacity: 1 - 1/16" Tap

Spindletype: CT 40 / BT

Length of Table: 44" Through Unlimited

Stroke X for Milling: 10"

Stroke Y for Milling: 24" Through 42"

Speed X-Axis: 1000 in/min

Speed Y-Axis: 200 in/min

Speed Z-Axis: 200 in/min

DrillCam Software

• 3D simulation: includes collision detection, time calculation and the ability to generate 3D parts from 2D views or files.

• Machining: Can machine until 2.5 axis, define multiple operations for each feature, and define user-specific clamping systems.

• Tooling Parameters: Can define tooling parameters and cutting conditions per material.

Hydralic Clamping System

The FlexBeam Profile Drilling Center incorporates a state-of-the-art hydraulic clamping system, ensuring secure and reliable fixation of workpieces during drilling operations, thereby enhancing safety and precision in profile drilling tasks.