- Products

- Catalogs

- News & Trends

- Exhibitions

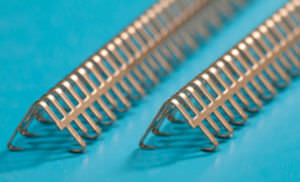

Rivet hinge fastener conveyor belt fastener SR™ seriesfor industrial applicationsstainless steelgalvanised steel

Add to favorites

Compare this product

Characteristics

- Type

- rivet hinge fastener

- Product applications

- for industrial applications

- Material

- stainless steel, galvanised steel, alloy

- Other characteristics

- high-performance

Description

The Flexco® SR™ Rivet Hinged Fastening System is ideal for use on rubber-plied and PVC solid woven belting and for worn belts unfit for vulcanized splices, delivering performance and long life with easy installation.

•Mechanical fastener rating from 330 to 2000 PIW (60 to 350 kN/m)

•Belts from 1/8” to 1” after skiving

•Pulley diameters from 5” to 42” (125 to 150 mm)

•Low-profile, Scalloped Edge® design is conveyor component compatible

•Hinged splice – easily separated to remove, extend, or clean belts

•Rivet-attached for maximum resistance to pull out

•Perfect for worn belting unfit for vulcanizing

To maximize fastener service life, fastener material must be matched to the application. Flexco manufactures fasteners from a broad range of materials. Our selection makes it easy to specify a fastener that will deliver maximum performance in a variety of conditions—from wet and abrasive applications to highly corrosive environments.

Galvanized Steel: For basic applications, galvanized steel is recommended. It is magnetic, offers good abrasion and rust resistance, but is not recommended for corrosive environments.

Stainless Steel: Stainless steel provides extra resistance to abrasion, magnetic attraction, and corrosion from acids and other chemicals.

MegAlloy®: Features superior resistance to wear and abrasion. Provides several times the service life of steel. Not recommended where

impact of corrosion is a problem.

RustAlloy®: Low chrome stainless steel. Resists corrosion from mine water and other types of chemical attack.

VIDEO

Related Searches

- FLEXCO belt fastener

- Roller brush

- Surface treatment roller brush

- FLEXCO metal belt fastener

- Washing roller brush

- Conveyor belt cleaner

- FLEXCO secondary conveyor belt cleaner

- FLEXCO conveyor belt pre-cleaner

- Conveyor skirt board

- Impact bed

- FLEXCO urethane conveyor belt pre-cleaner

- Lateral guide for conveyor

- FLEXCO tungsten carbide secondary conveyor belt cleaner

- Belt tracker

- Conveyor belt tracker

- Polyurethane conveyor belt cleaner

- Staple conveyor belt fastener

- Urethane secondary conveyor belt cleaner

- Polyurethane secondary conveyor belt cleaner

- Roller lateral guide for conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.