- Products

- Catalogs

- News & Trends

- Exhibitions

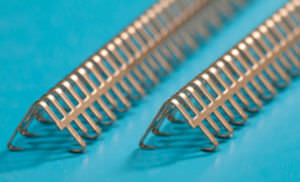

Bolt hinged conveyor belt fastener 375X/550 series stainless steelcoppersilicone

Add to favorites

Compare this product

Characteristics

- Type

- bolt hinged

- Material

- silicone, stainless steel, galvanised steel, alloy, copper

Description

The Flexco® Bolt Hinged Fastening System is ideal for belt conveyor applications subject to length adjustments because the joint can be separated easily by removing the hinge pin. A combination of penetration and compression delivers strength and reliability to belts operating over smaller pulleys.

• Mechanical fastener rating from 190 to 300 PIW (33-52 kN/m)

• Belts from 1/4” to 5/8” (6 mm to 16 mm) thick

• Pulley diameters from 6” to 9” (150 mm to 225 mm)

• Hinged fastener with easy-to-install nuts and bolts

• Easy joint separation with pin removal

• Perfect for applications with belts operating over small pulleys

• Specially formed teeth penetrate belt carcass for added strength without damaging fibers

• Piloted bolts for quick and easy installation

• Curved templet aids in accurate placement of bolt holes and uniform tension across the full belt end

To maximize fastener service life, fastener material must be matched to the application. Flexco manufactures fasteners from a broad range of materials. Our selection makes it easy to specify a fastener that will deliver maximum performance in a variety of conditions—from wet and abrasive applications to highly corrosive environments.

Galvanized Steel: For basic applications, galvanized steel is recommended. It is magnetic, offers good abrasion and rust resistance, but is not recommended for corrosive environments.

Stainless Steel: Stainless steel provides extra resistance to abrasion, magnetic attraction, and corrosion from acids and other chemicals.

MegAlloy®: Features superior resistance to wear and abrasion. Provides several times the service life of steel. Not recommended where

impact of corrosion is a problem.

VIDEO

Catalogs

Related Searches

- FLEXCO belt fastener

- Roller brush

- Surface treatment roller brush

- FLEXCO metal belt fastener

- Washing roller brush

- Conveyor belt cleaner

- FLEXCO secondary conveyor belt cleaner

- FLEXCO conveyor belt pre-cleaner

- Conveyor skirt board

- Impact bed

- FLEXCO urethane conveyor belt pre-cleaner

- Lateral guide for conveyor

- FLEXCO tungsten carbide secondary conveyor belt cleaner

- Belt tracker

- Conveyor belt tracker

- Polyurethane conveyor belt cleaner

- Staple conveyor belt fastener

- Urethane secondary conveyor belt cleaner

- Polyurethane secondary conveyor belt cleaner

- Roller lateral guide for conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.