- Products

- Catalogs

- News & Trends

- Exhibitions

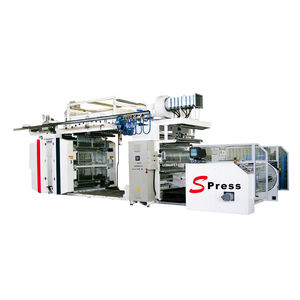

Flexographic press DH-ROC

Add to favorites

Compare this product

Description

The versatile press for every printer. A modern flexographic press, for the production of high-quality printing, with the following characteristics:

• quick job changes features, combined with relevant printing speeds, that makes it ideal for short and medium/long runs;

• print length and width range covering a wide field of the packaging and pre-print market.

Designed with a modular concept, including a rationally selected standard equipment, is prepared for future implementations to grant its updating according to the market demands.

Gear-less drive

Adopting direct drive technology, with “Servo-driven Motion”, provides features such as:

• Infinite intermediate print lengths;

• Precision and consistency of the print lengths;

• Register precision;

• Minimum preparation time;

• Reduced maintenance.

The most operator’s friendly design.

The horizontal extension of the printing units offers relevant advantages.

Easy access to all printing units facilitating job change-overs and any operational control. Full accessibility at operator’s hands with feet always on the floor.

• no lifting and climbing carrying weights;

• all controls on hand.

Ample space for fitting different and extended dryers and curing systems.

• Each printing unit is provided with an individual drying section adapted to the specific needs. No drying limits with colours over-printing, less solvent retention and higher realistic production speed;

• Unlimited flexibility and HYBRYD printing technology.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.