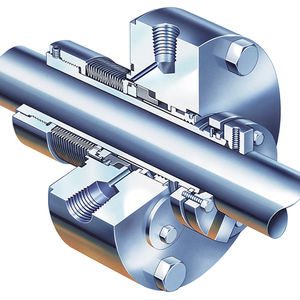

Spring mechanical seal GF-200for pumpprocess

Add to favorites

Compare this product

Characteristics

- Type

- spring

- Applications

- for pump

- Domain

- process

- Operating pressure

35 bar

(508 psi)- Operating temperature

Min.: -40 °C

(-40 °F)Max.: 260 °C

(500 °F)

Description

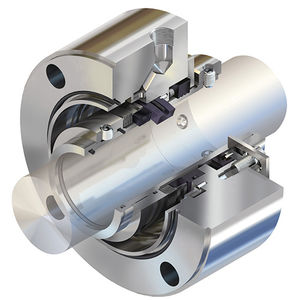

Flowserve GF-200 dual seals are non-contacting, gas barrier seals used in applications where no emissions of hazardous pumped products can be tolerated. Advanced Pattern Groove System provides low speed lift-off, low gas leakage and no face contact.

Dual seal pressurized with an inert gas barrier operates with zero process emissions to satisfy environmental monitoring requirements

Silicon carbide seal faces use APGS Precision Face Topography to separate the faces with a stiff, thin gas film that prevents wear and extends seal life

The LoDragTM O-ring technology provides consistent dynamic O-ring squeeze to reduce drag and maintain proper seal face tracking

Seal faces are optimized by geometry, materials, spring loads, and drive mechanisms to remain flat under all operating conditions and deliver long-term, reliable performance

Non-contacting seal faces require very low power consumption during start-up and running operation

Up to 35.4 bar (500 psi), -40 to 260°C (-40°F 500°F), up to 25 m/s (83.3 fps), 25.4 to 152 mm (1.000 to 6.000 inch)

Catalogs

Related Searches

- Mechanical seal

- Pump mechanical seal

- Metal mechanical seal

- Spring mechanical seal

- Cartridge mechanical seal

- Balanced mechanical seal

- Mechanical seal for the chemical industry

- Composite mechanical seal

- Face mechanical seal

- Carbon mechanical seal

- Bellows mechanical seal

- Process industry mechanical seal

- PTFE mechanical seal

- Corrosive liquid mechanical seal

- Mechanical seal for the pharmaceutical industry

- Mixer mechanical seal

- Steel mechanical seal

- Bi-directional mechanical seal

- Chemical process mechanical seal

- OEM mechanical seal

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.