- Power Transmission - Mechanical components

- Actuator and Positioning System

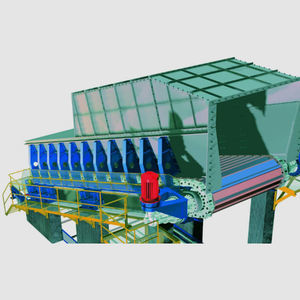

- Volumetric feeder

- FLSmidth MAAG® Gears and drives

Volumetric feeder ABON®modularconveyorchain

Add to favorites

Compare this product

Characteristics

- Type

- volumetric

- Operating mode

- modular

- Product applications

- conveyor, chain

- Other characteristics

- modular

Description

Free-flowing design insensitive to sticky materials

Robust chain design virtually eliminates breakage

Low conveyor speeds = low wear

Modular construction for easy delivery and installation

Top of the feed chain

You need a feeder that provides reliable, uninterrupted and controlled flow of raw material. Our ABON® Chain Feeder, with its heavy, robust build, is designed to provide your operation with reliable service for an excess of 20 years.

ABON® Chain Feeder for consistent, controlled feed

The ABON® Chain Feeder is an ideal primary feeder. It is designed to transfer material from the feed side towards the discharge “head chute” side of the feeder at a constant volumetric rate.

Comprising flight bars attached at regular intervals between two endless, linked feeder chains, the flight bars serve to transfer material at a consistent speed to the discharge end.

Unique feeder

These feeders have several unique features that set them apart from other feeder types and models:

The ABON® Chain Feeder’s modular design allows the unit to be broken down into components weighing no more than 10 metric tons (11 short tons) each. Thus, the unit may easily be transported or barged to your site and quickly assembled.

The modular construction accepts a wide range of lengths, allowing you to reduce your retaining wall height.

Because all of the modules are keyed and bolted, they hold their own loads when connected

Catalogs

Other FLSmidth MAAG® Gears and drives products

Cement

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.