- Packing - Handling - Logistics

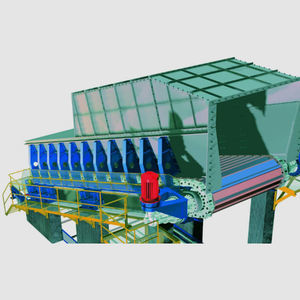

- Conveying

- Parts pneumatic conveying system

- FLSmidth MAAG® Gears and drives

Bulk pneumatic conveying system Airlift™transportcementparts

Add to favorites

Compare this product

Characteristics

- Product applications

- bulk, transport, cement, parts, conveying

Description

High reliability

Maintenance-free (no rotating parts)

Compact and easy to operate

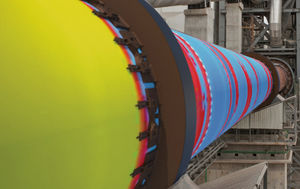

Temperature resistant up to 300°C

Completely dust-free operation

Vertical pneumatic conveying of fine-grained and powdery dry bulk materials

Sometimes, the only way to go is up. Mechanical conveying systems can get you there, but what about the dust? The maintenance? The Airlift™ vertical pneumatic conveying system is a clean, safe and low-maintenance option that can transport material to heights of more than 100 m at rates of up to 1000 t/h.

Airlift™: a real high-flyer in the world of pneumatic conveying

Vertical transportation of up to 1000 t/h dry bulk materials is a fixture in many applications. But transporting fine-grained and powdery bulk materials to heights of 100 m or more is challenging. Mechanical conveying systems tend to have a lot of moving parts and that means maintenance. Any dust escaping the system is an environmental concern and a safety issue.

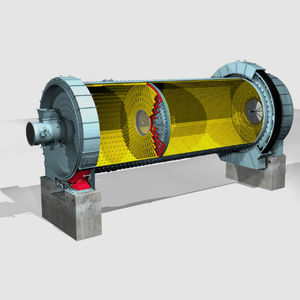

The Airlift™ is a pneumatic conveying system designed for vertical transport of these kinds of dusty, dry bulk materilas materials. With hundreds of applications worldwide in cement, lime, gypsum, power and aluminium plants, among others, the Airlift™ is a proven low-maintenance solution with zero dust when connected to a dust collection system. Throughputs up to 1000 t/h are possible. A conveying height of more than 100 m can be achieved. And the equipment can be tailored to transport materials with temperatures up to 300˚C.

The Airlift™ doesn’t use any mechanical or drive elements and is therefore not subject to wear like conventional vertical conveyors.

Catalogs

No catalogs are available for this product.

See all of FLSmidth MAAG® Gears and drives‘s catalogsOther FLSmidth MAAG® Gears and drives products

Cement

Related Searches

- Rail conveyor

- Transporting conveyor

- Horizontal rail conveyor

- Feeder

- Inclined conveyor

- Materials handling conveyor

- Bulk products conveyor

- Screw conveyor

- Feeding conveyor

- Discharge conveyor

- Loading conveyor

- Pneumatic conveying system

- Construction conveyor

- Bulk feeder

- Weighing system

- Gravity conveyor

- Trough conveyor

- Air conveyor

- Spiral conveyor

- Belt feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.