- Packing - Handling - Logistics

- Conveying

- Pneumatic conveyor

- FLSmidth MAAG® Gears and drives

Air conveyor constructioncansvehicle

Add to favorites

Compare this product

Characteristics

- Technology

- air

- Sector

- construction

- Transported product

- cans, vehicle

- Other characteristics

- for transport, silo, enclosed, gravity, loading, distribution

Description

Very low maintenance, with no moving parts

Completely enclosed, dust-free system

Extremely low energy costs

Maximum flexibility thanks to extensive accessory options

Dense phase conveying, for high throughput

Low-maintenance, low-energy fluidized conveying of dry bulk materials

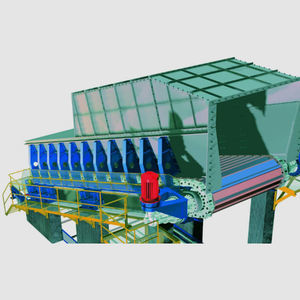

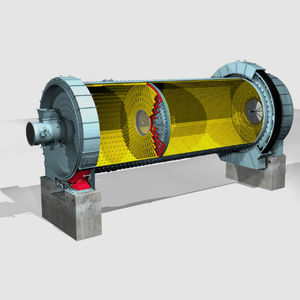

FLSmidth's Airslide fluidized conveying systems harness the power of gravity, giving you a system that is low maintenance, high efficiency and high performance. Through effective fluidization technology, throughputs of more than 2000 m3/h are possible with very low energy consumption.

Airslide: a fluidized conveying system that just makes sense

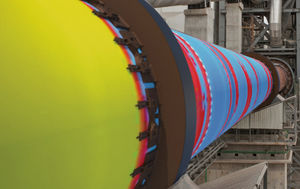

With minimal fluidizing air and a gentle incline, Airslide Conveyors transport dry and fine-grained mineral bulk materials economically and efficiently.

Working at speeds of 2000 m3/h and more, these enclosed fluidized conveying systems are dust-free, low wear and low maintenance, yet highly efficient. They can be used across the plant, in applications such as conveying bulk material from silos to vehicle or ship loading facilities, receiving material from bucket elevators for further distribution to silo chambers, or where multiple material flows meet for transport on to a common station.

Thanks to the low conveying speed and simple construction, Airslide conveys even high volumes of materials gently, without segregation and with very low wear. This gives you a long equipment life with virtually no maintenance.

Our Airslide Conveyors are built with flexibility in mind, so we’ve designed a variety of attachments and accessories to enable a broad range of uses.

Catalogs

No catalogs are available for this product.

See all of FLSmidth MAAG® Gears and drives‘s catalogsOther FLSmidth MAAG® Gears and drives products

Cement

Related Searches

- Rail conveyor

- Feeder

- Materials handling conveyor

- Bulk products conveyor

- Screw conveyor

- Discharge conveyor

- Loading conveyor

- Construction conveyor

- Pneumatic conveying system

- Bulk feeder

- Inclined conveyor

- Weighing system

- Gravity conveyor

- Air conveyor

- Spiral conveyor

- Belt feeder

- Wide conveyor

- Industry feeder

- Distribution conveyor

- Inspection conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.