- Production Machines

- Other Manufacturing Equipment

- Ball mill

- FLSmidth MAAG® Gears and drives

Ball mill horizontallarge

Add to favorites

Compare this product

Characteristics

- Technology

- ball

- Orientation

- horizontal

- Other characteristics

- large

Description

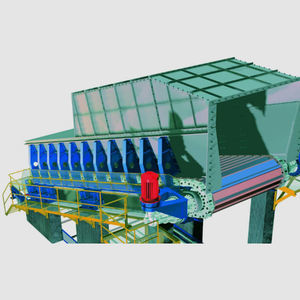

High reliability – over a century of experience with 4000+ ball mills installed globally

Large through-flow area ensures low pressure drop across the mill

Horizontal slide shoe bearing design allows much simpler foundations and reduced installation height

Increased effective grinding area with Stanex diaphragm design

Highly wear resistant liners to achieve longer availability of the mill

Cement grinding with our highly efficient ball mill

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just that.

The ultimate ball mill – with flexibility built in

You can’t optimise cement grinding with a one-size-fits-all solution. That’s why our ball mills are designed to adapt to your requirements, with a high degree of flexibility built in.

You decide whether to operate the mill in open or closed circuit, with or without a pre-grinder and with side or central drive, according to your plant layout and end product specifications. Even the lining types are tailored to your operating parameters.

This customised approach ensures you get maximum grinding efficiency with minimal maintenance.

In addition, the large through-flow areas enable the mill to operate with large volumes of venting air and a low pressure drop across the mill. This reduces the energy consumption of the mill ventilation fan and keeps your energy costs down.

Catalogs

No catalogs are available for this product.

See all of FLSmidth MAAG® Gears and drives‘s catalogsOther FLSmidth MAAG® Gears and drives products

Cement

Related Searches

- Grinding mill

- Screening unit

- Bulk material screening unit

- Horizontal grinding mill

- Roller grinding mill

- Compact grinding mill

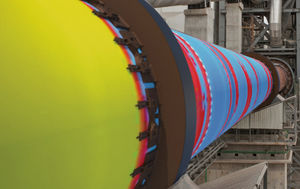

- Rotary drum grinding mill

- Ball grinding mill

- Heavy-duty screening unit

- Variable speed grinding mill

- Large grinding mill

- Wedge wire screen

- Vertical roller grinding mill

- Slot wedge wire screen

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.