- Materials - Tools - Components

- Standard Mechanical Component

- Rectangular seal

- FLSmidth MAAG® Gears and drives

Rectangular seal graphiteplasticoil

Add to favorites

Compare this product

Characteristics

- Configuration

- rectangular

- Material

- graphite, plastic

- Application

- oil

- Fluid

- air, gas

- Other characteristics

- flexible

Description

Lower operating and maintenance costs

Superior flame shaping

Increased firing of alternative fuels

Long refractory life

Lower emissions

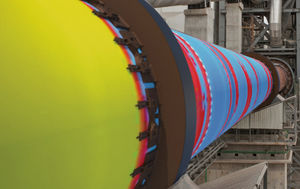

Efficient conventional and alternative fuel firing with our kiln burner

With a unique design utilising fixed or rotatable rectangular jet air nozzles, our JETFLEX® Kiln Burners offer maximal flexibility for solid pulverised and alternative fuel firing. Fast and easy shipping keeps initial costs low, while a common solid fuel channel reduces usage of cold fuel-conveying air.

Our high-substitution-rate kiln burner for alternative fuels firing

Our JETFLEX® Burner is a highly flexible kiln burner, designed to produce the best flame shape and lowest NOx emissions for various fuel types and operating conditions. It fires rotary kilns with pulverised coal or coke, oil, natural gas, or any mixture of these fuels. Alternative fuel firing of plastic chips, wood chips and sewage sludge can also occur through the same common fuel channel.

The JETFLEX Burner is available for any fuel combination and maximum capacity ranging from 10 to 250 MW, catering for even the largest of rotary kilns. The primary air supply to the kiln burner enables a flame momentum of 7 N/MW up to 11 N/MW.

We offer two kiln burner models: The standard JETFLEX® Burner and the JETFLEX® PLUS Burner.

JETFLEX Burner

Keeping it simple, the standard JETFLEX Burner has no moving parts, offering easy operation and reliability as fewer parts are exposed to wear. The kiln burner flame shape or momentum is easily controlled by simple regulation of the primary air pressure and flow.

Catalogs

No catalogs are available for this product.

See all of FLSmidth MAAG® Gears and drives‘s catalogsOther FLSmidth MAAG® Gears and drives products

Cement

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.