- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Pneumatic fitting

- FLSmidth MAAG® Gears and drives

Pneumatic fitting screw-inelbowplastic

Add to favorites

Compare this product

Characteristics

- Applications

- pneumatic

- Attachment

- screw-in

- Configuration

- elbow

- Material

- plastic, polymer, polyethylene, iron, ceramic

- Other characteristics

- abrasion-resistant

- Diameter

Min.: 75 mm

(2.953 in)Max.: 300 mm

(11.811 in)

Description

Durable, long lasting design

Reduces the development of fines and streamers

Customizable end connection to meet plant requirements

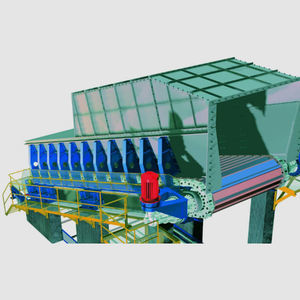

Abrasion resistant ceramic pipe fittings for pneumatic conveying

Abrasion is a two-way problem. It wears down your equipment – and the materials being transported are degraded. Reducing abrasion is therefore a priority. Our abrasion resistant ceramic pipe fittings are up to the task. Durable. Customizable. Effective.

Low on maintenance, high on quality

When you're transporting any materials through your pneumatic conveying system, you have two concerns: efficient delivery and safe transport. Abrasion has a negative impact on both.

When the abrasive materials rub against the interior of the pipeline, they cause wear that could ultimately put that pipeline out of operation. Meanwhile, that friction also stresses the materials – and in the case of polymer plastics can give rise to dust, streamers, angel hair and other prettily named but unwelcome phenomenon.

Our abrasion-resistant pipeline fittings are designed to prevent both of these problems. The diamond-shaped pipe elbow interior finish was developed for durability. It resists abrasion and dramatically reduces the occurrence of fines and streamers. And because we know that process plants come in all shapes and sizes, the fittings are available in a range of configurations to meet your pipeline layout needs.

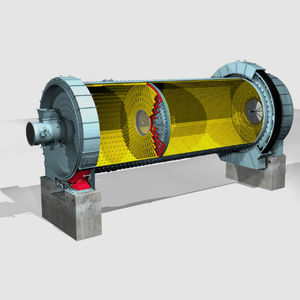

Our abrasion resistant ceramic pipe fittings are manufactured from 450-Iron for all kinds of abrasive bulk materials. We also have cast aluminum pipe fittings range developed especially for transporting plastic pellets

Materials typically handled include:

• PVC

• Polyethylene

Catalogs

No catalogs are available for this product.

See all of FLSmidth MAAG® Gears and drives‘s catalogsOther FLSmidth MAAG® Gears and drives products

Cement

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.