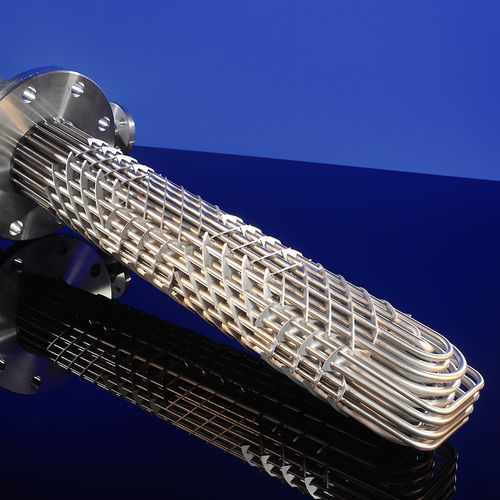

The design of the mixer / heat exchanger equates to a combination of a static mixer and a multitube heat exchanger in which a highly viscous product on the shell side flows through the static mixer. The advantages of these two distinct systems are aggregated for use at laminar flow.