- Industrial machines and equipment

- Heat Exchanger and Refrigeration

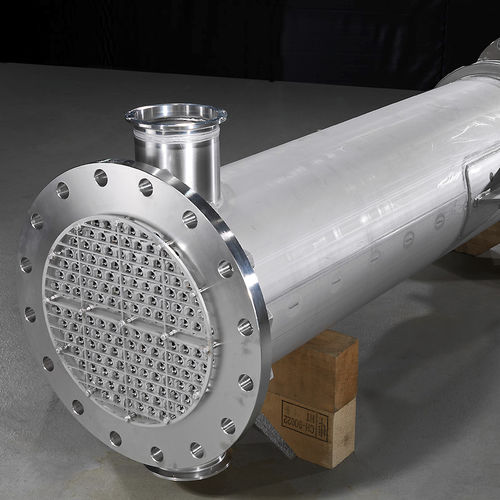

- Shell and tube heat exchanger

- Fluitec mixing + reaction solutions AG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Shell and tube heat exchanger shell and tubeliquid/liquidgas/liquid

Add to favorites

Compare this product

Characteristics

- Type

- shell and tube, shell and tube

- Fluid

- liquid/liquid, gas/liquid

- Material

- stainless steel, titanium, nickel, steel

- Other characteristics

- compact, high-performance, corrosion-resistant, custom, for corrosive fluids, counter-current

- Applications

- industrial, for the food industry, for the petrochemical industry, for the chemical industry, for the pharmaceutical industry, for the paper industry, for the plastics industry, for viscous products, for the automotive industry, for thermal fluid boilers

- Power

Max.: 10,000 kW

Min.: 0.1 kW

- Operating pressure

Max.: 200 bar

(2,900.75 psi)Min.: 0 bar

(0 psi)- Temperature

Max.: 400 °C

(752 °F)Min.: -100 °C

(-148 °F)

Description

Multitube heat exchangers with mixing elements in the multitubes are ideal for product viscosities between 50 and approximately 500 mPas. Various static mixing elements can be installed in the multitubes depending on the heat transfer application. These elements increase the heat transfer from the product to the tube wall, so that smaller sizes can be realised than if the multitube heat exchanger has no mixing elements.

Multitube heat exchangers are not suitable for processeswhere the residence time is critical or for cooling tasks where the viscosity increases significantly (risk of maldistribution). The Fluitec CSE-XR® mixer / heat exchanger is recommended as an alternative for these applications.

Catalogs

No catalogs are available for this product.

See all of Fluitec mixing + reaction solutions AG‘s catalogsOther Fluitec mixing + reaction solutions AG products

Mixer/Heat-Exchanger

Related Searches

- Heat exchanger unit

- Liquid agitator

- Homogenizer for the food industry

- Vertical agitator

- Liquid/liquid heat exchanger

- Stainless steel agitator

- Agitator for the chemical industry

- In-line mixer

- Horizontal blender

- Agitator for the pharmaceutical industry

- Tubular heat exchanger

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Homogenizer for the cosmetics industry

- Compact agitator

- Industrial heat exchanger unit

- Compact heat exchanger unit

- High-speed homogenizer

- Vacuum homogenizer

- Disperser homogenizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.