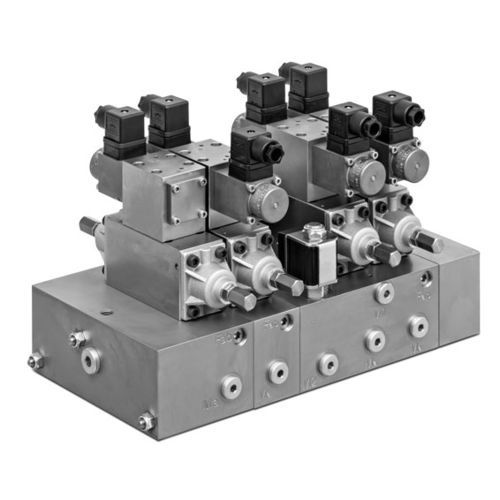

Base plate hydraulic directional control valve MEV seriesspoolpilot4/3

Add to favorites

Compare this product

Characteristics

- Type

- spool

- Actuating method

- pilot

- Ports/positions

- 4/3, 4/2, 3/2-way

- Other characteristics

- proportional, base plate

Description

The MEV is a proportional 4/3, 4/2 or 3/2-way valve. It is usually used as part of an overall configuration. Various spools are available.

The shape of the AMCA proportional control valve coil is different from other conventional coils. The result is a progressive flux curve. To make the best use of the coil’s maximum stroke, the inlet or outlet angle of the A and/or B port can be adjusted for higher flows. For constant flow, the pressure drop across the orifice of the spool remains constant, regardless of the load pressure.

The operation of the proportional directional valve with electrically controlled pilot stage (MEV) is explained below. When solenoid a is actuated, it pushes the control spool (control piston) toward solenoid b and opens spool cross-section 1. This releases control pressure to spring chamber 1 (speed controlled by adjustable orifice 5) and through orifice 3 to the end of the spool opposite solenoid a. The balancing force on the control spool is the force of the solenoid, which is proportional to the electrical input signal. The balancing force corresponds to the control pressure in the solenoid b and also in the spring chamber 1.This pressure presses the main spool against the spring in the spring chamber 2 and thus assumes a position proportional to the electrical input signal. The screws on the spring chambers can be used to limit the maximum flow by screwing in the screws and thus limiting the stroke of the main spool.

Catalogs

No catalogs are available for this product.

See all of Fluitronics GmbH‘s catalogsRelated Searches

- Electrically operated valve

- Directional control valve

- Hydraulic directional control valve

- Spool hydraulic directional control valve

- Electrically-operated hydraulic directional control valve

- Manual hydraulic directional control valve

- Compact hydraulic directional control valve

- 4-way hydraulic directional control valve

- Solenoid-operated hydraulic directional control valve

- Proportional hydraulic directional control valve

- 3-way hydraulic directional control valve

- Pilot-operated hydraulic directional control valve

- Electro-hydraulic hydraulic directional control valve

- Lever-operated hydraulic directional control valve

- 3/2 hydraulic directional control valve

- Sectional hydraulic directional control valve

- Cast iron hydraulic directional control valve

- Modular hydraulic directional control valve

- Hydraulically-operated hydraulic directional control valve

- High flow rate hydraulic directional control valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.