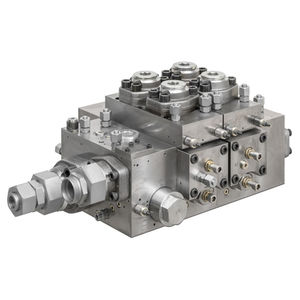

Spool hydraulic directional control valve APV-22lever-operatedcompactproportional

Add to favorites

Compare this product

Characteristics

- Type

- spool

- Actuating method

- lever-operated

- Other characteristics

- compact, proportional, sectional, modular

- Operating pressure

Min.: 6 bar

(87 psi)Max.: 420 bar

(6,092 psi)- Flow rate

320 l/min, 380 l/min, 660 l/min

(85 us gal/min, 100 us gal/min, 174 us gal/min)

Description

The AMCA APV control valve series is a highly modular valve design that is available in sectional and plate body designs. The APV series comes in four different sizes, APV10, APV16, APV22 and APV32 and covers a flow range between 80 l/min and 1000 l/min. It further features high pressure range up to 420 bar, low hysteresis and the optional salt and seawater resistant Protalloy coating. A worldwide dealer network of build partners can help you implement your solution.

The spool section is the central base. It consists of a spool section (I), basic or custom manifold blocks (II), and spring and end pens (III). In the APV10, for example, a maximum of 15 parallel sections are possible.

Conventional directional control valves control the start, stop and movement directions of hydraulic motors and cylinders. However, the speed of these users depends on the load pressure. If this load pressure varies then the speed is hardly controllable.

The AMCA proportional directional valves of the APV series are pressure compensated and achieve ideal control of force, speed, acceleration and deceleration, regardless of load and increased requirements. Load compensation is provided by the hydraulic pressure compensator (1), the spool at the bottom of the section.

There are different types of actuation for the APV section valve (2). Besides manual actuation, there are hydraulic actuation type and electric actuation type of the main spool.

Mobile sectional control valve.

Catalogs

Related Searches

- Electrically operated valve

- Directional control valve

- Hydraulic directional control valve

- Spool hydraulic directional control valve

- Electrically-operated hydraulic directional control valve

- Manual hydraulic directional control valve

- Compact hydraulic directional control valve

- 4-way hydraulic directional control valve

- Solenoid-operated hydraulic directional control valve

- Proportional hydraulic directional control valve

- Lever-operated hydraulic directional control valve

- Electro-hydraulic hydraulic directional control valve

- Pilot-operated hydraulic directional control valve

- 3-way hydraulic directional control valve

- Sectional hydraulic directional control valve

- 3/2 hydraulic directional control valve

- Modular hydraulic directional control valve

- Hydraulically-operated hydraulic directional control valve

- Cast iron hydraulic directional control valve

- Normally closed hydraulic directional control valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.