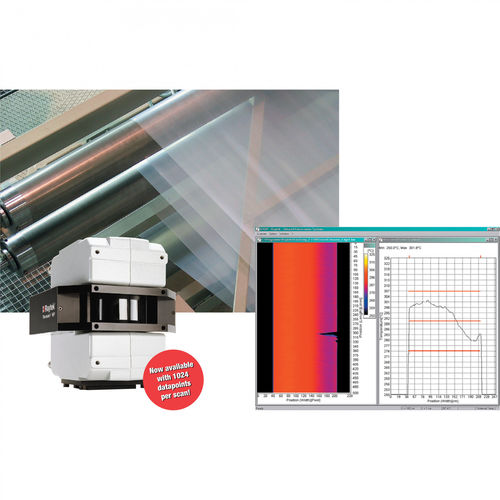

Thermal imaging system based on the Raytek MP150 infrared linescanner.

Detailed web temperature profile based on 40,000 measurement points per second

Automated temperature monitoring

Automated quality monitoring for ISO9000

Ensures proper web temperatures for strong film-to-substrate adhesion

Enables plant operators to reduce scrap and improve profitability and product quality

Quick and automatic detection of “wavy” or “running” edges, gaps, and torn edges

Define product-specific configurations (recipes)

Automatically analyze “automatic sector” temperature distributions

Visualisation on PC

Playback stored files as “movie”

Multiple language support

Integrated OPC server for remote system control

Ethernet TCP/IP interface integrated in the line scanning system

PC-independent alarm output

Analog outputs 3 x 4 – 20mA

Analog or digital output modules

For sheet extrusion see the Raytek ES150 system.